Expert Tips

Understanding the Carbon Numbers in a Wood EPD

Guidance on how global warming potential and biogenic carbon are reported in the North American Softwood Lumber Environmental Product Declaration

Recommended pre-reading: How to Include Biogenic Carbon in an LCA. For more information on whole building life cycle assessment, biogenic carbon and carbon storage, and environmental product declarations, visit our Sustainability page. View a complete list of sustainability resources here.

An environmental product declaration (EPD) is a summary of life cycle assessment (LCA) results for a particular product. While there are limitations to how EPDs can and should be used, they provide useful data for a wide range of potential environmental impacts, including global warming potential (GWP). GWP is a measure of anthropogenic (human-caused) greenhouse gas emissions and is reported for all types of materials. However, when looking at biobased products such as wood, carbon accounting becomes more complex because biogenic carbon (carbon stored within the wood fibers through photosynthesis during tree growth) is also tracked. This article will explain how biogenic carbon and GWP are reported in the Softwood Lumber Environmental Product Declaration, co-published by the American Wood Council and Canadian Wood Council.

Although this paper is specific to North American softwood lumber, the parameters tracked are similar for EPDs of other North American wood products. For engineered and composite wood products (i.e., glulam, I-joists, LVL, etc.), additional material resource inputs (e.g., adhesives) are included within the product system of the EPD. A compilation of EPDs for other structural wood products can be found here. Because EPDs developed outside North America are often based on different standards or product category rules (PCR),1 they may not be consistent with the information provided in this article.

Biogenic Carbon Reporting Requirements

Like many EPDs for construction materials, the system boundary of the North American Softwood Lumber EPD is cradle-to-gate, which means it tracks environmental flows during the Production Stage, (information modules A1-A3). The PCR that establishes the requirements for wood product EPDs in North America specifies that biogenic carbon accounting shall be in accordance with ISO 21930,2 Section 7.2.7. This section states, in part:

The amount of biogenic carbon contained within biobased material leaving the product system shall be declared as technical scenario information in the module where the material is leaving the product system, irrespective of whether the environmental impacts and aspects of this module are declared.

It goes on to say:

For bio-based packaging material, the quantity of biogenic carbon […] contained within the packaging […] shall be declared in information module A5 […]. For construction products, the quantity of removals of biogenic carbon […] shall be documented at the end-of-life stage in information modules C3/C4 […].

Simply put, this section says that, even when information modules A5 and C3/C4 are not declared in the EPD, the biogenic carbon stored in the product system must still be reported within these information modules.

Although the North American Softwood Lumber EPD only declares modules A1-A3 (i.e., it does not declare modules A4-C4), in order to follow ISO 21930, the EPD still reports the biogenic carbon stored in the wood product in modules C3/C4 (Waste Processing and Disposal). This reporting method is based on the most conservative end-of-life assumption—that all biogenic carbon will eventually leave the product system. Reporting this export of biogenic carbon at the material’s end of life ensures that, even when only considering cradle-to-gate impacts, the most conservative end-of-life assumption is included and transparently reported, resulting in no net biogenic carbon storage over the product’s life cycle. Additional discussion about biogenic carbon end-of-life options can be found here.

Additionally, although it does not represent a significant portion of the carbon in the product system, packaging material does contain some biogenic carbon in the form of paper wrap, cardboard, wood spacers, etc. Following ISO 21930, this biogenic carbon is reported as entering the system in module A3, during manufacturing, and leaving the system in module A5, as waste during construction.

Biogenic Carbon Reporting in the EPD

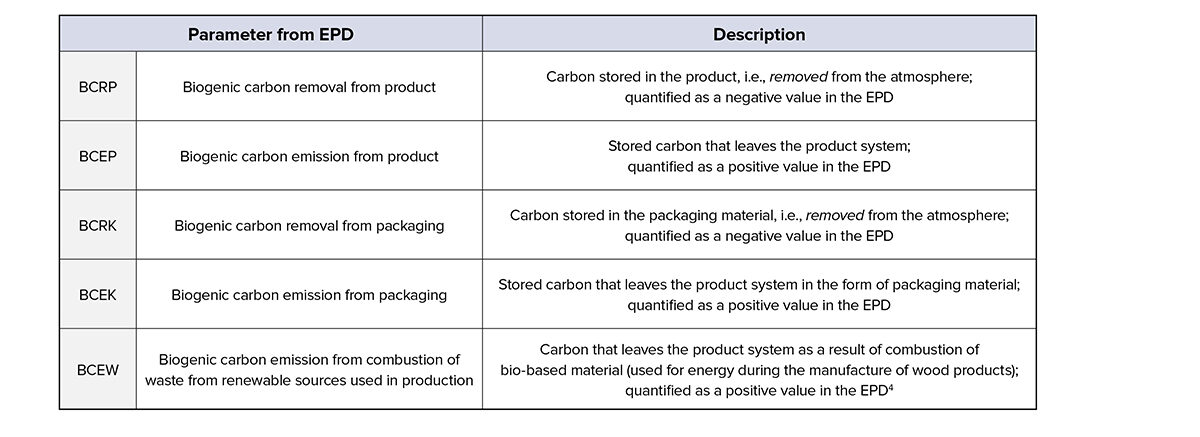

Within the EPD, biogenic carbon flows are tracked through several parameters, as described here: 3

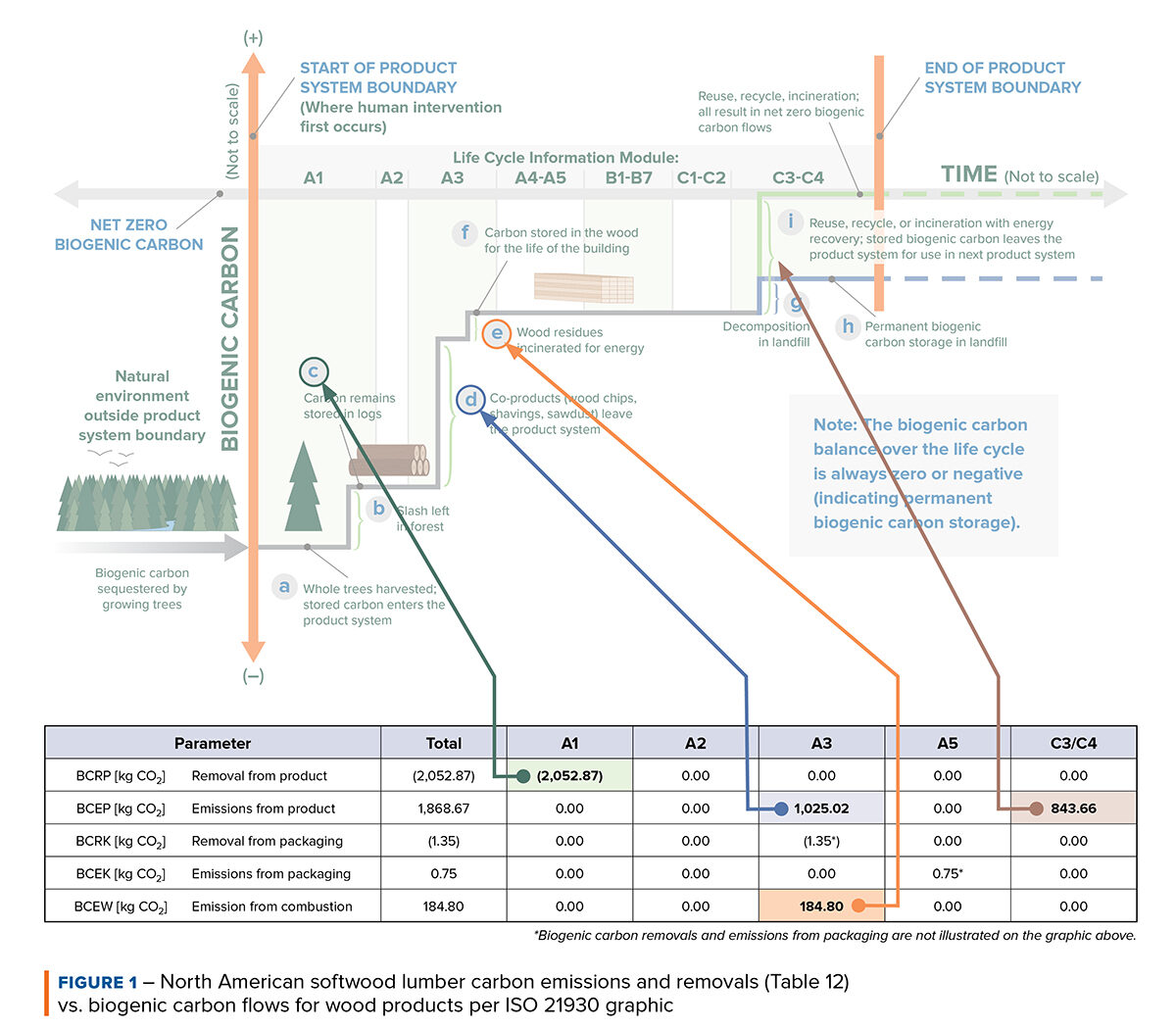

In the North American Softwood Lumber EPD, biogenic carbon values (in units of kg CO2 eq/m3) are reported in Table 12. To better understand these values, it is helpful to consider them in relation to the Biogenic Carbon Flows for Wood Products per ISO 21930 graphic, which was introduced in the WoodWorks article, How to Include Biogenic Carbon in an LCA. An annotated version of this graphic is shown in Figure 1.

The negative BCRP value in module A1 represents the amount of carbon stored in the logs when they leave the forest (point c). Once at the mill, the round logs are cut into rectangular dimensional lumber. The positive BCEP and BCEW values in module A3 represent the biogenic carbon stored in wood fiber residues generated during manufacture (e.g., debarking and planning). These residues leave the product system and do not physically end up in the final lumber product. BCEP is for co-products that leave the product system for other uses (point d), and BCEW is for wood residues recovered for energy during lumber production—e.g., heat for drying kilns (point e).

As discussed, the North American Softwood Lumber EPD conservatively assumes that all biogenic carbon stored in the lumber for the life of the building is exported at the end of life, resulting in net-zero biogenic carbon reporting. This is represented by the positive BCEP value in modules C3/C4 (point i). This value also represents the amount of biogenic carbon stored in the product system for the life of the building.5 As noted, biogenic carbon contained in packaging must also be counted. This carbon enters the system in module A3 as BCRK (with a small portion also leaving the system as emissions, included in the BCEW value). The packaging carbon then leaves the system during construction, in module A5 as BCEK.

Note that the accounting method currently used for North American wood product EPDs results in the following:

- Summing all the values in modules A1-A5 from Table 12 results in a value equal, but opposite in sign, to the BCEP value in modules C3/C4.

- When biogenic carbon values are summed over the entire life cycle (A1-C4), the result is zero.

Global Warming Potential Reported in the EPD

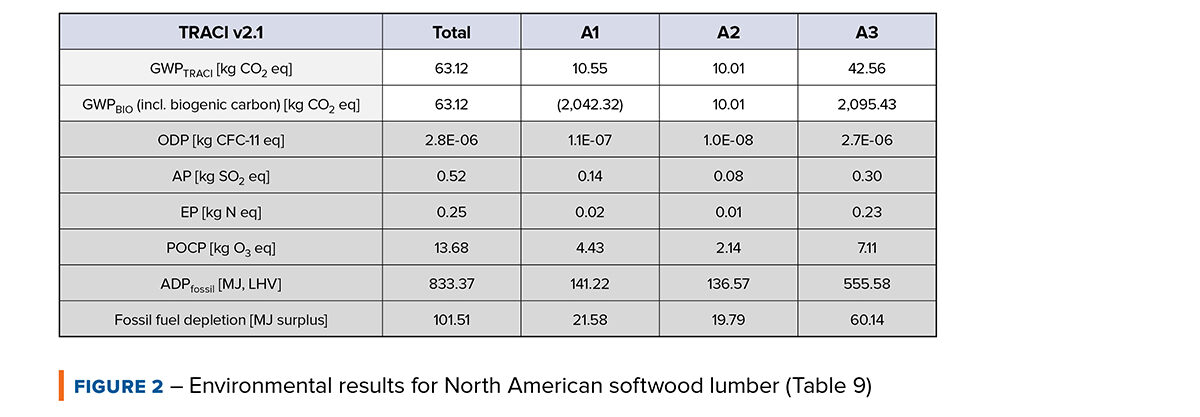

Greenhouse gases released into the atmosphere as a result of the extraction, transportation and manufacturing of a product are reported in terms of carbon dioxide equivalents as GWP. As recreated in Figure 2, Table 9 of the North American Softwood Lumber EPD reports two GWP values: GWPTRACI (global warming potential based on TRACI 2.16) and GWPBIO (global warming potential including biogenic carbon). The remainder of the factors in the table relate to other environmental impacts, which are outside the scope of this article.

GWPTRACI values represent embodied carbon emissions for each module during the cradle-to-gate life cycle stages.

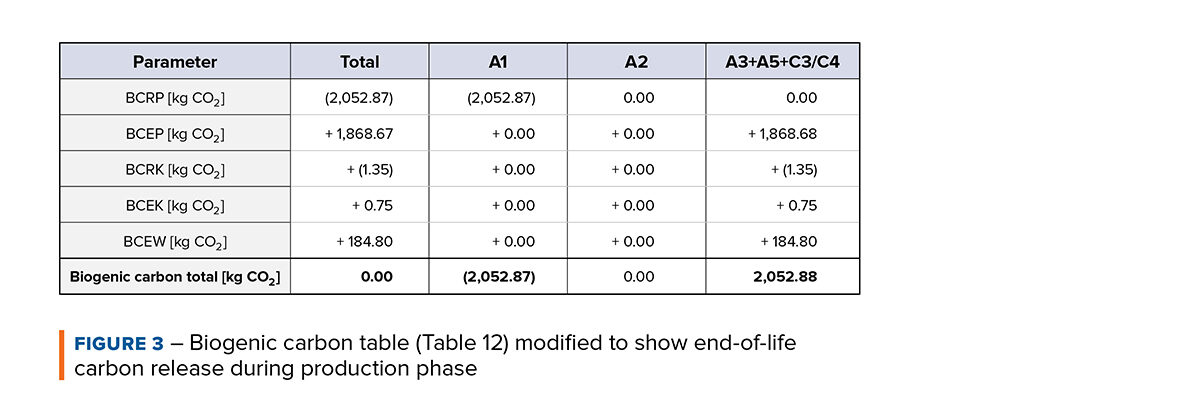

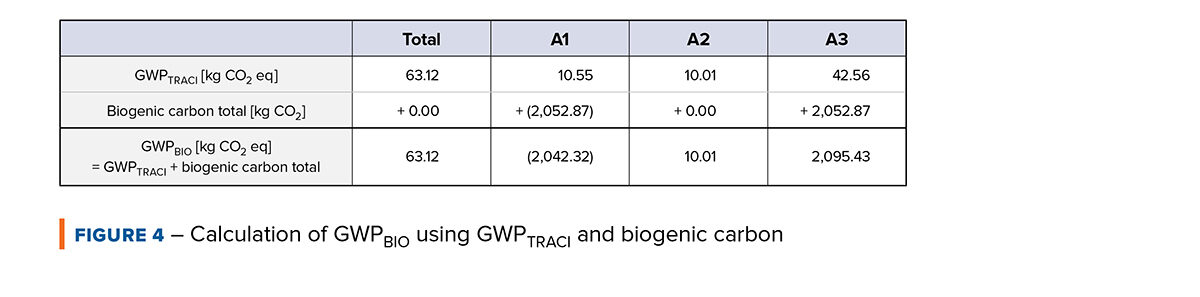

GWPBIO values are the summation of embodied carbon (GWPTRACI) plus biogenic carbon values. To account for the biogenic carbon values from modules A5 and C3/C4, they are added to the value reported in module A3. This calculation is outlined in Figure 3. The sum of the biogenic carbon value at each production phase is then added to the corresponding GWPTRACI value, resulting in the GWPBIO number. This calculation can be found in Figure 4.

Conclusion

Making sense of the data in an EPD allows designers to better understand the information used in an LCA, along with the potential environmental impacts associated with the production stage of wood products. A more complete picture of the environmental benefits of wood products in construction can be achieved through whole building life cycle assessment (WBLCA), which is discussed in depth in this article.

Additional Resources

American Wood Council and Canadian Wood Council. (2018, July). Environment Product Declaration: North American Softwood Lumber

U.S. Environmental Protection Agency. (2023). Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990-2021.

Hall, E. S. Think Wood. How to Calculate the Wood Carbon Footprint of a Building.

International Organization for Standardization. (2017). ISO 21930:2017 Sustainability in Buildings and Civil Engineering Works – Core Rules for Environmental Product Declarations of Construction Products and Services.

Ross, L. American Wood Council. (2021, October). AWC’s LCA, EPDs, GWP, and Other Abbreviations Explained.

Salazar, J. Carbon Leadership Forum. (2020, May). Wood Carbon Seminars: How LCA Handles Wood.

ThinkWood. Carbon Source to Carbon Sink: Redesigning the Built Environment for Climate Change.

UL Environment. (2018, August). Product Category Rules for Building-Related Products and Services, Part A: Life Cycle Assessment Calculation Rules and Report Requirements UL 10010 v3.2.

UL Environment. (2020, May). Product Category Rules for Building-Related Products and Services Part B: Structural and Architectural Wood Products EPD Requirements UL 10010-09 v1.1.

1 Product Category Rules (PCR) is a set of rules, requirements and guidelines used to develop an EPD for a specific product category. Construction products are typically categorized based on their material (e.g., wood) and their function (e.g., structural uses). A PCR is often developed for a specific geographical region (e.g., North America).

2 Part B: Structural and Architectural Wood Products EPD Requirements, Section 3.10

3 Adapted from North American Softwood Lumber EPD, Table 8

2 ISO 21930, Section 7.2.7

4 Note that carbon emissions due to combustion of biobased materials are net neutral based on the “-1 in/+1 out” biogenic carbon accounting framework outlined in ISO 21930 for biobased materials originating from sustainably managed forests. For more information on this topic, see When to Include Biogenic Carbon in an LCA.

5 Salazar, J., Miner, R., Oneil, E. Carbon Leadership Forum. (2020, May). Wood Carbon Seminars: Discussion Session 2 (LCA and Wood).

6 US Environmental Protection Agency. (2012, July). Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI) 2.1, TRACI 2.1 provides characterization factors for various atmospheric releases. These characterization factors are used to determine the impact that different greenhouse gases have on GWP over a 100-year time period.