Expert Tips

Code Requirements and Resources for Wood Stair Framing

Covers means of egress requirements, structural design, allowable materials and fire-resistance ratings, stair landings, guardrail posts, and available resources.

There are three main aspects of stair design dictated by code: means of egress component requirements, structural design, and allowable materials/fire resistance ratings.

Means of Egress Requirements

Stairway code requirements are partially detailed in Sections 1005.3.1 and 1011 of the 2018 International Building Code (IBC). These sections give requirements on design criteria such as egress width and capacity, allowable riser height, allowable tread depth, headroom, landing size, and stair construction.

Structural Design

When it comes to the structural design of stair stringers and treads, the code does not provide prescriptive design tables. Design of stringers, treads, and their connections are left to the structural engineer. Regarding structural design criteria, 2018 IBC Table 1607.1 (30) requires stairs to resist a minimum live load of 300 pounds (concentrated load) or 100 pounds per square foot (psf), or 40 psf for one one-and two-family dwellings. ASCE 7-16 Table 4.3-1 indicates the same loading. Deflection criteria is listed in 2018 IBC Table 1604.3 and is typically limited to L/360 for live load and L/240 for total load.

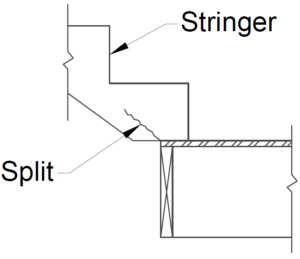

One approach with dimension lumber is to notch the stair stringers and consider only the depth of wood beneath the tread/riser notches as effective in resisting the applied load. This method goes outside notching requirements listed in the American Wood Council’s National Design Specification® for Wood Construction (NDS®), and engineering judgement should be used in its implementation. If using this approach, it is helpful to have a discussion with the Authority Having Jurisdiction to make sure it will be accepted. Care should be taken not to over-cut the limits of the notch, unnecessarily reducing the effective depth of the member.

In contrast to this approach, some designers prefer to use the notched stringer as a form to attach riser and tread boards, and to sister another full-depth piece of dimension or engineered lumber to the side of the stringer to serve as the structural member.

An approach for narrower stair sections is to keep the two outer stringers whole (unnotched) and provide a wood-bearing block or manufactured steel angle on the inside face beneath each tread. The block or angle acts as a short ledger for the tread.

While dimension lumber has been and continues to be successfully implemented for stair stringer construction, the structural properties of engineered wood products such as structural composite lumber (SCL) may be desirable in some situations. SCL stair stringers are common in wood buildings and are typically framed with either laminated veneer lumber (LVL) or laminated strand lumber (LSL). Pre-cut stringers are available from various suppliers in both dimension and engineered lumber. Several manufacturers have resources available to help designers specify the correct size of stringer, including:

- US Western 1-5/16″ Versa-Lam 1.4 1800 Stair Stringer Guide

- US Eastern 1-1/2″ Versa-Lam 1.7 2650 Stair Stringer Guide

- Sturdistep Stair Treads

- TimberStrand LSL Stair Stringers and SturdiStep Stair Treads Specifier’s Guide

Connection of the top of stair stringers to landings is often accomplished using manufactured steel hangers. Several companies make adjustable slope hangers for both dimension and engineered wood products that make these connections easy to install and provide reliable capacity. The bottoms of stair stringers often bear on top of landings or the floor below. At landings, care should be taken to avoid extending the back of the horizontal bottom cut beyond the limits of the landing to prevent splitting of the stringer.

Allowable Materials and Fire Resistance Ratings

2018 IBC Section 1011.7 indicates that stairways must be built of materials that are consistent with the construction type. That generally means Types V and III for light-wood frame construction, and Type IV for heavy timber. In podium buildings where the lower portion is of Type IA construction, and the building above is Type III, IV, or V, there is also a path to use wood framing for the entirety of stairs in the stair enclosure. To read more on this topic, see our Ask an Expert post here.

Stair Landings

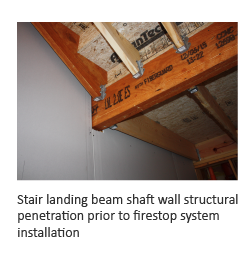

When framing a stair landing, questions often arise on the proper way to install a landing beam or floor joist that is making a membrane penetration of a rated wall assembly for the stair enclosure. Membrane penetrations must comply with 2018 IBC Section 714.4.1 (via 714.4.2) where either:

- Penetrations shall be installed as tested in an approved fire-resistance-rated assembly (i.e., incorporated during the conduct of an ASTM E119 test of the wall or floor assembly, per IBC Section 714.4.1.1) or, more commonly,

- Protected by an approved penetration firestop system installed as tested in accordance with ASTM E 814 or UL 1479, with an F (flame) rating of not less than the required fire-resistance rating of the wall penetrated (per IBC Section 714.4.1.2).

Both options provide a code-compliant path to beam membrane penetrations. An example of a compliant system is located here. Firestop manufacturers are also able to provide engineering judgments with their products if the design application does not fit previously tested configurations.

Stair landing framing attached to shaft wall through two layers of gypsum prior to landing beam hanger installation

In other instances, ledgers are installed to support framing such that drywall is sandwiched between wall studs and the ledger board. Several manufacturers have products that can be used in such conditions and available resources, including:

- MiTek – WSWH5 – Attaching Ledger-to-Studs with One or Two Layers of 5/8″ Gypsum Wallboard

- Simpson Strong Tie – SDWS Timber Screws with Gypsum Board Interlayer(s)

For further discussion on shaft walls and associated issues, see the WoodWorks paper, Shaft Wall Solutions for Wood-Frame Buildings.

Guardrail Posts

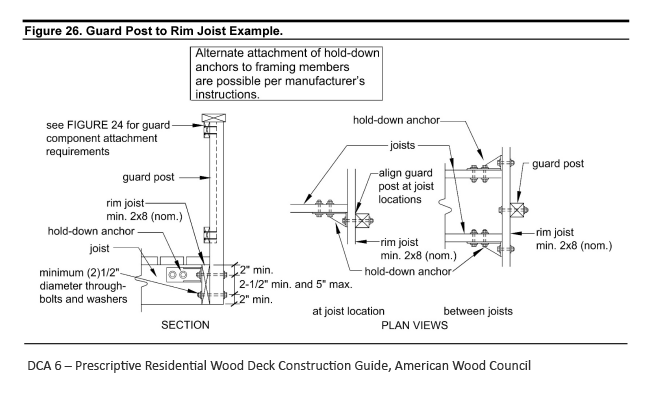

When an open stairway is specified, guardrails must be attached to stair framing. 2018 IBC 1607.8.1 and ASCE 7-16 Section 4.5.1.1 require handrail and guardrail systems to resist a 50 pounds per linear foot (plf) load applied in any direction along the handrail or top rail. The system must also be designed for a non-concurrent 200-pound concentrated load (IBC 1607.8.1.1 & ASCE 4.5.1). Fastening of guardrail posts to landing framing or stringers is an important component in this system. For wood post options, manufactured tension ties are a good way to resist resulting overturning forces at the base of the post. Below are some resources that address this attachment; while they speak mainly to residential decks, the same concepts apply to commercial construction.

- AWC DCA 6: Prescriptive Residential Wood Deck Construction Guide

- Design and Testing of Residential Deck Guard Rail Connections

- Tested Guardrail Post Connections for Residential Decks.