Expert Tips

Holes and Penetrations in Mass Timber Floor and Roof Panels

Guidance for the design of mass timber floor and roof panels with openings, including structural, fire resistance, and acoustic impacts, and tips for reinforcement.

It is common to have holes and openings in mass timber floors panels—including cross-laminated timber (CLT), nail-laminated timber (NLT), dowel-laminated timber (DLT), etc.—to allow for vertical passage of MEPF elements. In some cases, the openings are small (e.g., for plumbing pipes or electrical conduit); in other cases, they’re significant (e.g., for large ducts or shaft enclosures). In addition to the structural impacts of interrupting a mass timber floor or roof panel, thought should be given to the impact that openings have on the assembly’s fire-resistance continuity and acoustical performance.

Structural Impacts of Openings in Mass Timber Floor and Roof Panels

There aren’t any U.S. design guides or standards that directly address how to prescriptively assess what holes and openings are acceptable without reinforcing in CLT floor and roof panels. What holes are acceptable without supplemental framing will depend on the panels used, loading on the project, and size and location of holes relative to the panel layout and span. Each condition can be evaluated on a project-by-project basis; however, it is possible for a design team to establish some standard structural details and allowances based on known panel properties, stress ratios, loading conditions and other parameters. That said, for coordination and fabrication, it is beneficial to model as many of the penetrations and holes in mass timber systems as possible. This helps ensure that the mass timber manufacturer fabricates the panels with the openings (rather than having to make adjustments in the field). Shop-fabricated openings usually provide more accuracy in terms of opening dimensions and location and often a cleaner aesthetic.

There are different levels of analysis that can be performed to evaluate the structural impacts of openings. A simple method is to perform what is called a “strip analysis” of the panel around the opening. This can be done using hand calculations of assumed strips of the panels surrounding the holes idealized as beams. For CLT in particular, keep in mind the major vs. minor flexural and shear strength and stiffness values. This method is also described as a “grillage” of substitute beams. An example from Europe can be found in Section 4.2 of the Pro:Holz Cross-Laminated Timber Structural Design, Volume 2.

Since the strip analysis method simplifies the full plate behavior, it doesn’t tend to be extremely accurate for the prediction of deflections. Similarly, take care not to rely on this method to be highly precise in predicting local demands. In summary, this simple method can be useful for simple checks but is best not used to justify designs that are very close to being overloaded.

A more in-depth analysis involves a finite element model (FEM) plate analysis of the force distribution around openings in panels. CLT is orthotropic, meaning it has different structural properties in different orthogonal directions, and some structural analysis tools will not handle the mechanics of orthotropic CLT plates. However, an orthotropic thick-plate analysis could be used to create an engineering model of the behavior, provided the major strength and minor strength direction properties are modeled to match the panel properties.

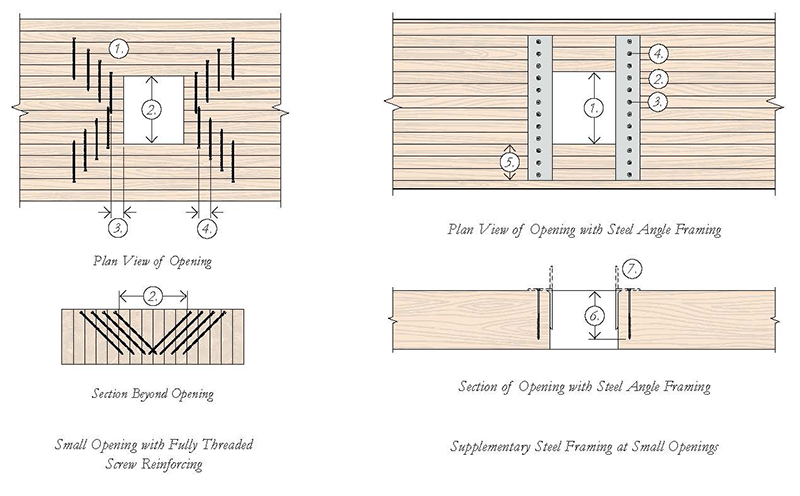

Mass timber panel products such as NLT and DLT can also accommodate holes and openings but are one-way spanning systems, so the analysis methods may vary from those used in CLT. Section 4.4.2 of the Nail-Laminated Timber U.S. Design and Construction Guide provides prescriptive opening design and reinforcing strategies as a function of opening size:

- Small openings (9 inches wide or less)

- Large openings (greater than 9 inches)

The NLT guide notes that small holes for conduit or pipe (typically up to 3 inches in diameter) can usually be accommodated without additional reinforcing. Openings between 3 and 9 inches may require reinforcing in the form of inclined screws or steel angles. Large openings require reinforcing such as steel angles or dropped beams below the NLT panels. Regardless of opening size, the engineer should evaluate each opening based on the applicable loads and panel stresses, as well as location relative to panel edge, diaphragm edge, span and supports, etc.

The Dowel-Laminated Timber Design Guide & Profile Handbook by StructureCraft notes that DLT panels can typically accommodate openings up to 12″ in diameter without additional reinforcement, while larger openings are possible with screw reinforcement.

Fire Resistance and Acoustical Impacts of Openings in Mass Timber Floor and Roof Panels

To maintain the continuity and integrity of fire resistance-rated assemblies, penetrations must be properly sealed and protected in accordance with IBC Section 714. Note that Sections 708.7, 707.7, 713.8 and 712.1.4, which cover penetrations in fire partitions, fire barriers, shaft enclosures and horizontal assemblies (respectively), all point to section 714 for their protection.

Section 714.5.1 addresses penetrations in horizontal assemblies, and gives the following options for demonstrating acceptable protection measures:

- Through penetrations shall be protected using systems installed as tested in the approved fire-resistance-rated assembly, or

- Through penetrations shall be protected by an approved through-penetration firestop system installed and tested in accordance with ASTM E814 or UL 1479, with a minimum positive pressure differential of 0.01 inch of water (2.49 Pa). The system shall have an F rating/T rating of not less than 1 hour but not less than the required rating of the floor penetrated.

Credit: AWC/FPInnovations

Of the two options, the more common route for demonstrating protection of penetrations through mass timber floor panels is the use of firestop systems tested in accordance with ASTM E814 or UL 1479. Several tests have been conducted for these conditions on mass timber assemblies, which have achieved F and T ratings up to 2 hours. A summary of these tests is included in the WoodWorks Inventory of Fire Resistance-Tested Mass Timber Assemblies & Penetrations.

Even when the floor assemblies in a mass timber building are carefully designed and installed for high acoustical performance, consideration of flanking paths—in areas such as assembly intersections, beam-to-column/wall connections, and MEP penetrations—is necessary for a building to meet overall acoustical performance objectives.

Specifically at MEP openings, flanking paths can be minimized with proper sealing products. With airtight connections, interfaces and penetrations, there is a much greater chance that the acoustic performance of a mass timber building will meet expectations.

For additional information on the acoustic design of mass timber elements, see the WoodWorks publication Acoustics and Mass Timber: Room-to-Room Noise Control.