Expert Tips

Flame Spread Class and Mass Timber

Understanding flame spread class and how to verify adequate protection of mass timber

Photo Nick Johnson, Tour D Space

This article references the 2024 International Building Code (IBC) and 2024 International Mechanical Code (IMC).

Flame spread class is a rating used to indicate how quickly flames can spread over the surface of a material. It is primarily a consideration for finish materials—i.e., materials exposed to the interior of a building in its final condition—and the flame spread characteristics of these materials impact the fire dynamics of the structure. Flame spread is typically measured using a standardized test method. IBC Section 803.1.2 recognizes two test method standards that can be used to evaluate the flame spread characteristics of materials: ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials, and UL 723, Test for Surface Burning Characteristics of Building Materials. These tests are technically equivalent and measure the speed and extent of flame spread and smoke density of materials under controlled conditions. The resulting numbers are the flame spread index (FSI) and smoke developed index (SDI). The FSI and SDI are then compared to standardized ranges, which determine the resulting flame spread class defined in the IBC.

The ASTM E84 and UL 723 tests involve mounting a 24-foot-long material sample in an 18-inch tall by 12-inch wide by 25-foot-long tunnel and exposing it to a controlled flame for 10 minutes. The FSI is determined based on the rate the flame progresses along the surface of the material, and the SDI is determined based on the amount of smoke emitted as the material burns. The results are then used to assign a flame spread class to the material, ranging from Class A (least combustible) to Class F (most combustible).

IBC Section 803.1.2 defines how interior wall and ceiling finish materials are grouped, utilizing Class A, B, or C. It states:

Interior wall and ceiling finish materials shall be classified in accordance with ASTM E84 or UL 723. Such interior finish materials shall be grouped in the following classes in accordance with their flame spread and smoke developed indices.

Class A: Flame spread index 0-25; smoke developed index 0-450

Class B: Flame spread index 26-75; smoke developed index 0-450

Class C: Flame spread index 76-200; smoke developed index 0-450

It is important to understand flame spread class when selecting materials for use in construction and other applications where fire safety is a concern. Materials with a higher flame spread class are more likely to contribute to the spread of fire and may be less suitable for use in certain applications. By selecting materials with a lower flame spread class, building owners and designers can help to reduce the risk of fire and protect both people and property.

IBC Flame Spread Class Requirements for Multi-Family and Commercial Projects

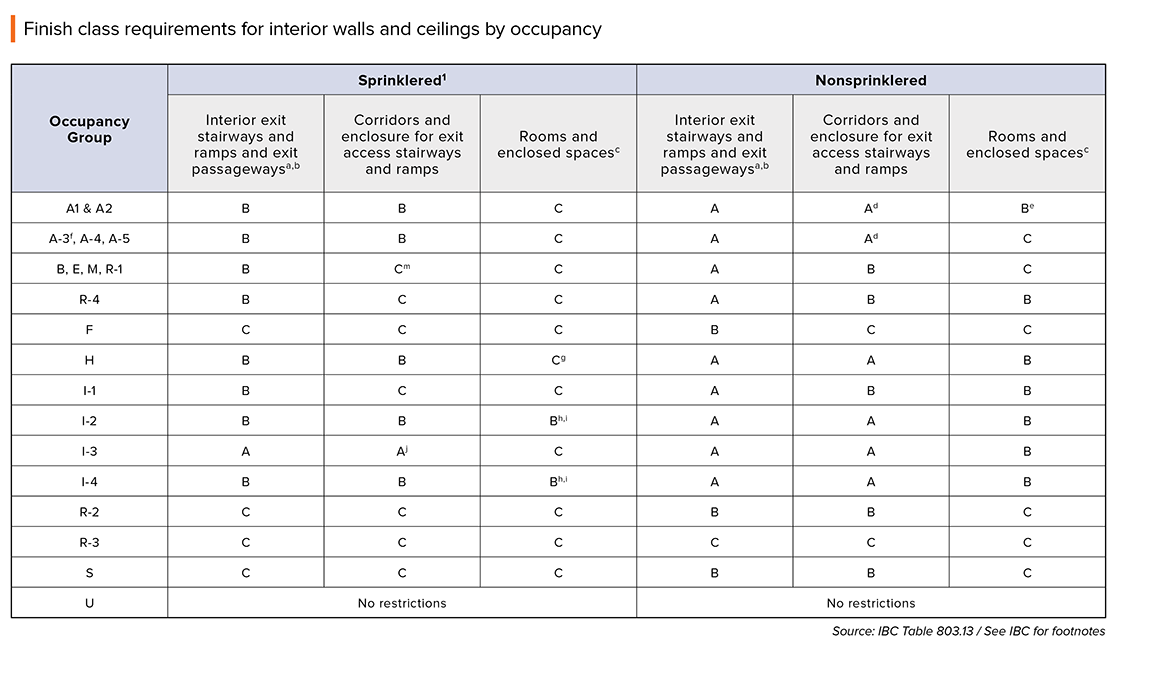

IBC Table 803.13 provides the minimum requirements for interior finish class (A, B, or C), which is a function of the building’s occupancy, whether or not it is sprinklered, and where in the building the finish is located. For sprinklered buildings, most occupancies and building areas specify a class B or class C finish per the table below.

Items to note in the above table:

- The required flame spread class of an interior finish is a function of the building’s occupancy and where the finish is located, not the construction type or structural materials. In other words, combustibility of the structural materials is not a factor when determining the flame spread class of interior finishes. Those requirements are the same in a multi-family building whether it is a single-story, Type V-B wood building or a 50-story, Type I-A steel and concrete high-rise (e.g., class C for group R-2 buildings).

- Finish flame spread class requirements vary based on whether the building is sprinklered. Nearly all modern buildings, regardless of their size, occupancy, or structural materials, have an automatic sprinkler system, either required in IBC Chapter 9 or influenced by an insurance provider or other factors. Mass timber and light-frame wood buildings are required to meet the same sprinkler standards (usually NFPA 13) as buildings constructed with other structural materials. Since nearly all modern multi-family and commercial buildings are sprinklered, the table above shows that only a few conditions require a flame spread class of A (group I-3 occupancy). All other occupancies and building elements permit class B or C interior finish materials.

Flame Spread Class Requirements for Exposed Mass Timber

In buildings with exposed mass timber framing, structure also functions as finish, making it necessary to consider the IBC’s interior finish provisions in addition to factors such as fire-resistance ratings. Section 803 covers wall and ceiling finishes, which are the most common applications of exposed mass timber. As noted, finishes in a sprinklered building need to meet a class B or C flame spread class, depending on the occupancy and their location within the building (expect occupancy I-3).

Mass timber elements meeting the requirements of heavy timber construction (minimum sizes as specified in IBC Section 2304.11) are exempt from the interior finish requirements except in specific egress passages as discussed in IBC Section 803.3:

Exposed portions of building elements complying with the requirements for buildings of heavy timber construction in Section 602.4 or Section 2304.11 shall not be subject to interior finish requirements except in interior exit stairways, interior exit ramps, and exit passageways.

The code commentary to this section clarifies the purpose for this exemption:

This section is simply intended to clarify the code regarding heavy timber, which is commonly exposed to the interior without any interior finish. The concerns over the contribution of heavy timber building elements to flame spread in a structure are dealt with in the general requirements of Chapter 6 and other provisions of the code that allow heavy timber.

Therefore, mass timber elements in any building, even those in construction types other than Type IV, are not subject to interior finish requirements. However, if a jurisdiction requires further justification when using mass timber as a finish element, the designer may choose to demonstrate that the exposed mass timber framing can meet the required class B or C flame spread, using the following information.

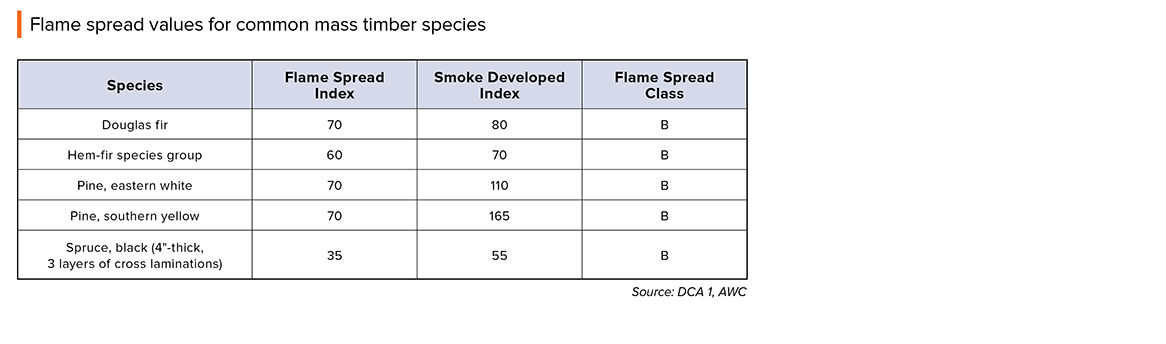

The American Wood Council’s (AWC’s) Design for Code Acceptance 1 – Flame Spread Performance of Wood Products Used for Interior Finish (DCA 1) lists flame spread values for a number of wood species and panel products. The table below, based on information in DCA 1 (from testing in accordance with ASTM E84), shows FSI and SDI values along with the resulting frame spread class for common species used in mass timber. These common species all achieve a class B rating. Some manufacturers have also performed ASTM E84 testing on their own mass timber products. Tested samples yielded results matching or exceeding those in DCA 1, further corroborating the class B rating.

For moisture protection during construction, base coatings are often applied to mass timber at the manufacturer’s facility. However, these coatings are not typically tested to ASTM E84 standards. This is due in part to the fact that, when base coatings are used, they are not always applied to all faces of the mass timber. For example, a coating might be applied to the top surface and sides of CLT panels to add moisture protection during construction but not the bottom surface since it is less likely to be exposed to moisture (thus reducing the coating cost). Where the bottom of the panel is the final exposed surface, and it doesn’t receive a base coating, the interior finish provisions allow the wood material to be used for the flame spread class, per DCA 1. Where the bottom of the panel does receive a base coating, IBC Section 803.2 provides a thickness exemption, whereby materials less than 0.036 inches thick, applied directly to the surface of the wall or ceiling, need not be tested.

Protective coatings are often applied to exposed mass timber during the last stage of construction, resulting in the final finish product. Where this is the case, several manufacturers make finish coating systems that comply with ASTM E84 and have a class A flame spread rating. Be sure to check the coating manufacturer’s product literature to ensure ASTM E84 standards are met. For more information on protective coatings, see the WoodWorks article, Architectural Finishes and Mass Timber

Using Mass Timber in Mechanical Plenums

One important consideration when using wood as the interior finish relates to mechanical plenums, such as those used for air supply. Since mechanical plenums create concealed spaces, they are subject to additional code requirements for fire protection and flame spread class. Concealed spaces are not typically allowed to contain combustibles other than electrical, mechanical, fire protection, or plumbing materials and equipment in accordance with Section 602 of the International Mechanical Code. Instead, materials in plenums are required to be either noncombustible or have an FSI of not more than 25 and an SDI of not more than 50, which would classify as flame class A. For this reason (and several others), mass timber elements within mechanical plenums typically require noncombustible coverings. For additional information on the protection of mass timber elements within concealed spaces, see the WoodWorks publication, Concealed Spaces in Mass Timber and Heavy Timber Structures.

Sections 803.1.2 and 803.3, and Table 803.13, are copyrighted excerpts from the 2024 International Building Code. Copyright © 2023. International Code Council, Inc. All rights reserved. Reproduced with permission granted by ICC in February 2026. www.ICCSAFE.org.

Commentary Section 803.3 is a copyrighted excerpts from the 2024 IBC® Code and Commentary—Volume 1. Copyright © 2024. International Code Council, Inc. All rights reserved. Reproduced with permission granted by ICC in February 2026. www.ICCSAFE.org.