Expert Tips

Detailing Floor-to-Exterior Wall Conditions in Type III Projects

Discusses common questions not clearly answered in the International Building Code, plus an example strategy and additional resources.

This article references the 2024 IBC.

Type III construction is typically used for five-story wood-frame residential projects, with or without a podium, and may also be used for six-story wood-frame office buildings. When designing these buildings, code requirements for wall and floor detailing come from many parts of the IBC.

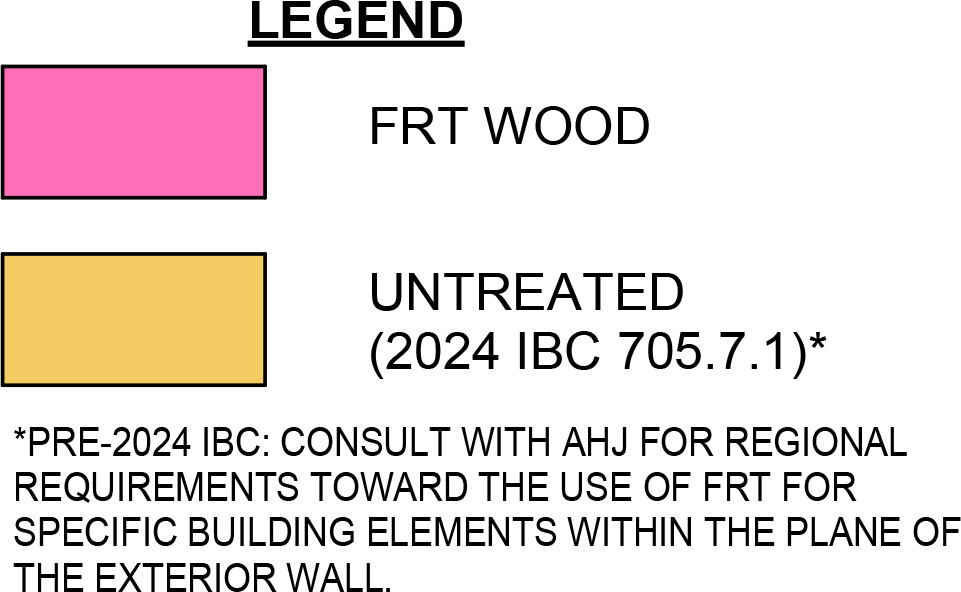

Under the International Building Code (IBC), exterior walls in Type III construction are required to be framed with non-combustible materials (Section 602.3) or fire retardant-treated wood (FRTW) (Section 602.4.4.1), while the floor and roof framing can be standard, untreated wood framing.

In Type III construction, exterior bearing walls must meet the more stringent requirement of both IBC Table 601 and Table 705.5, meaning the required fire-resistance rating is governed by the worst-case condition of the two tables. Exterior nonbearing walls, however, are governed only by the fire separation distance requirements in IBC Table 705.5 For occupancies other than Group H, a typical load bearing exterior wall in Type III, this means that the exterior wall must be 2-hour (IBC Table 601), while nonbearing exterior walls must be rated based upon the fire separation distance (IBC Table 705.5) which allows the exterior wall to be 1 hour fire-resistance rated if the fire separation distance is 5’ or more and potentially unrated (0 hour) if the fire separation distance is equal to or exceeds 30’. A metal or wood stud wall is defined as load-bearing if it supports more than 100 pounds per linear foot of vertical load in addition to its own weight. Learn more about load bearing wall assessment and design with the WoodWorks expert tip How to Determine if Exterior Walls are Load or Non-Load Bearing and Why That’s Important.

Floor framing assemblies in Type III construction can vary based upon construction type, with Type III-A requiring a 1-hour FRR and Type III-B requiring no rating (Table 601). However, other provisions of the building code may require additional fire-resistance based upon the occupancy. For example, residential occupancies require a 30-minute or 1-hour rating for the floor construction (Table 601, Sections 420.3 and 711.2.4.3).

As noted above, code requirements for exterior wall and floor detailing come from many parts of the IBC. For many multi-family construction projects this commonly results in a 2-hour rated, FRTW exterior wall and a 1-hour rated, untreated wood floor assembly. Taking this condition into consideration, the remainder of this article will focus on this common scenario. The intersection of these two assemblies raises some questions about fire-resistance and material continuity that were not historically addressed in the IBC:

- What fire-resistance continuity requirements exist for the 2-hour rated exterior wall through the depth of the 1-hour floor? Unlike provisions listed for fire-resistance continuity of fire walls, fire barriers and fire partitions, the IBC did not specify continuity requirements for exterior walls prior to the 2024 IBC.

- What material and FRR requirements exist where a wood floor assembly intersects and supports an exterior wall above? Again, the IBC did not historically contain language specific to continuity requirements of exterior walls prior to the 2024 IBC.

A challenge for building design and construction professionals is that there has been a significant variety in what is considered acceptable from one building jurisdiction to another. The 2024 IBC has addressed these challenges with additional language specific to the intersection of floor and exterior wall design within two specific sections:

- IBC 705.6 – Continuity

- This 2024 addition now addresses continuity of the FRR for exterior walls, stating that the rating must be continuous from the top of the foundation or floor/ceiling assembly below to one of the following:

- The underside of the floor sheathing, roof sheathing, deck or slab above

- The underside of a floor/ceiling or roof/ceiling assembly having a fire-resistance rating equal to or greater than that of the exterior wall and the fire separation distance exceeds 10 feet.

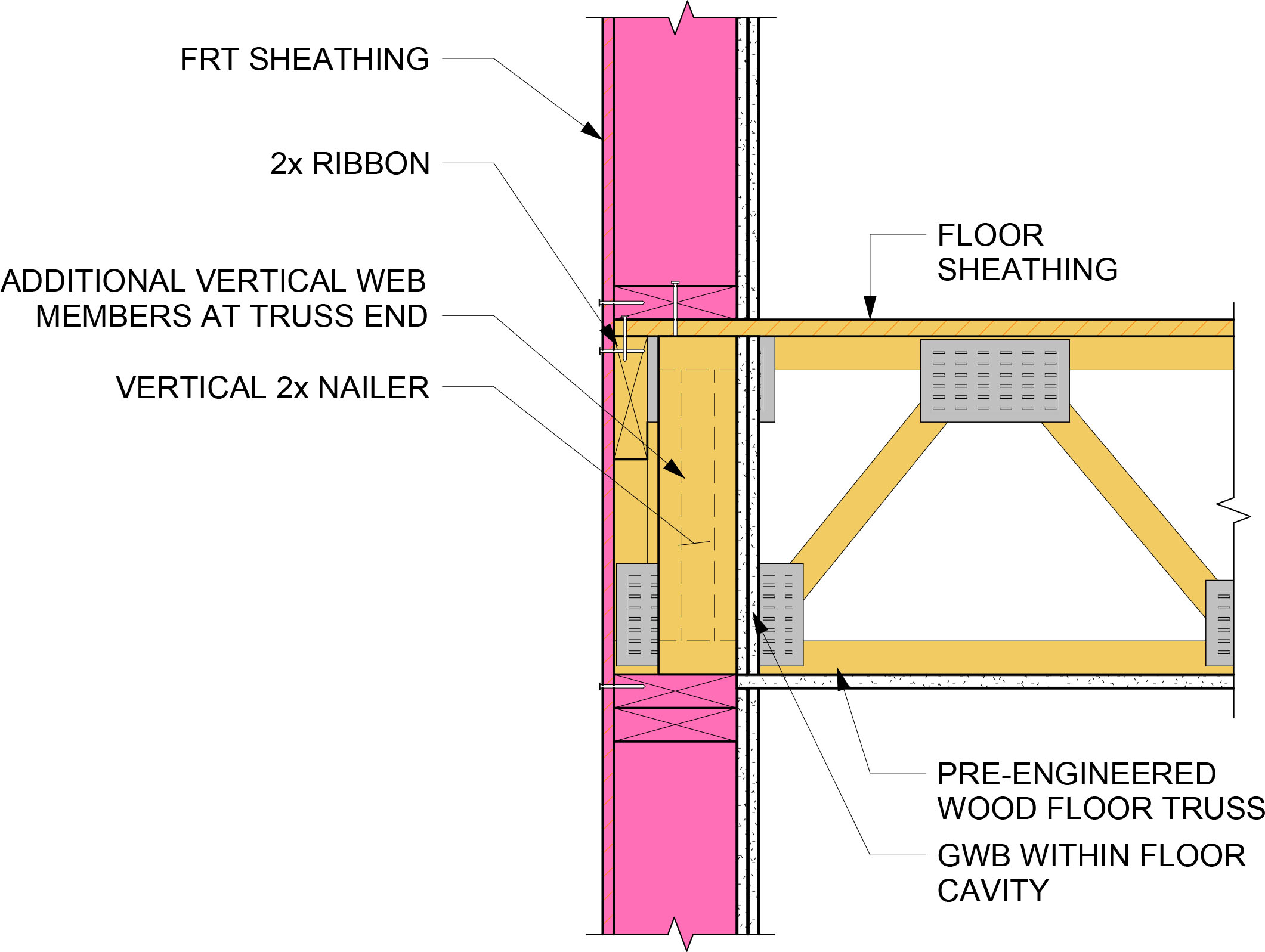

For most multifamily projects utilizing a 2 hour fire-resistance rated exterior wall and a 1 hour fire-resistance rated floor system, the code is now specific that the fire-resistance rating of the wall must be continuous to the underside of the floor or roof sheathing above. For the example of a 1-hour rated floor intersecting a 2-hour rated exterior wall, one option is to utilize semi-ballon framing, ensuring the wall assembly is continuous to the underside of the floor or roof sheathing; however, this often requires the gypsum on the interior face to run continuous to the top of the plates, which can create complications with gypsum membrane penetrations by the floor assembly components.

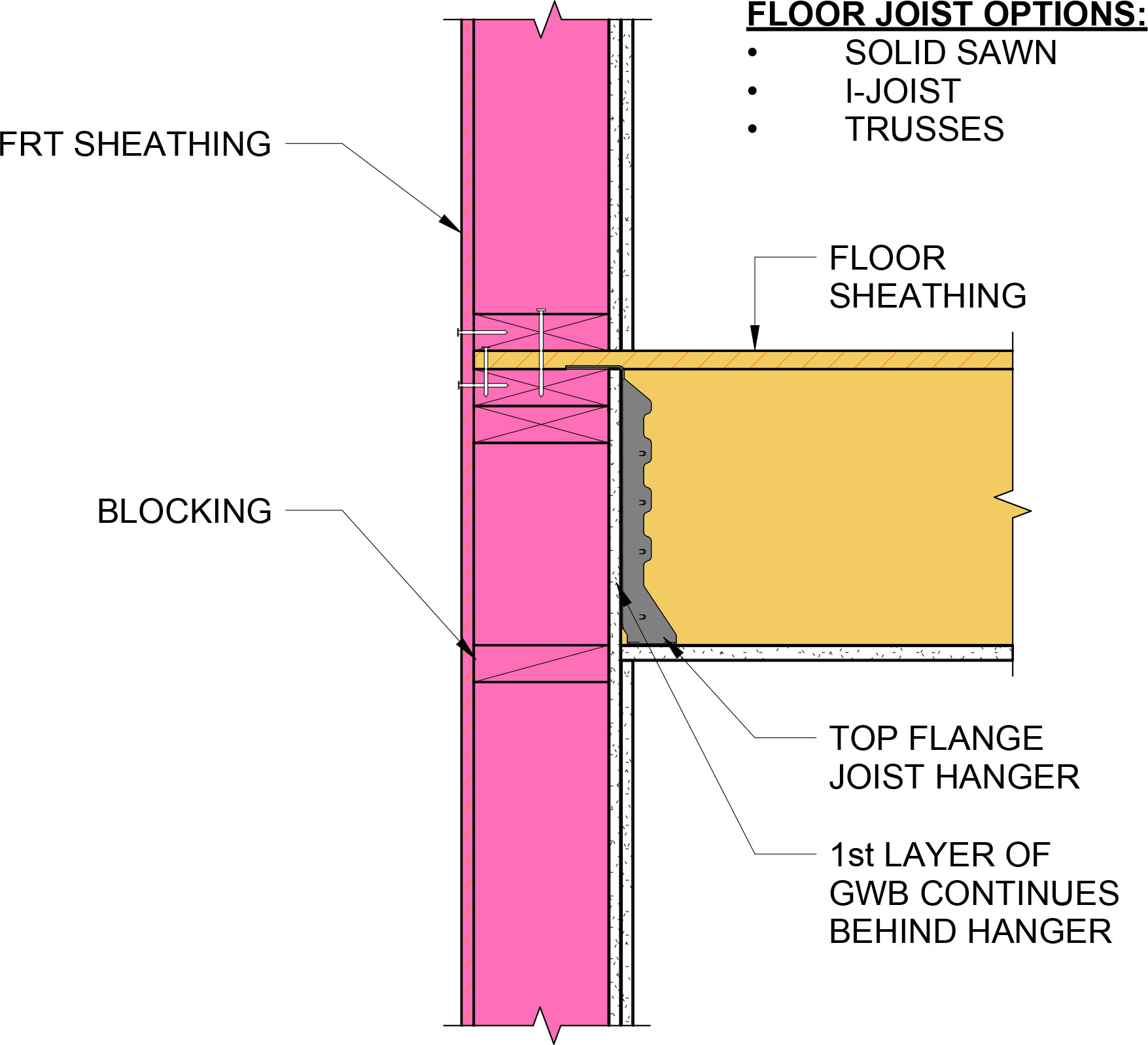

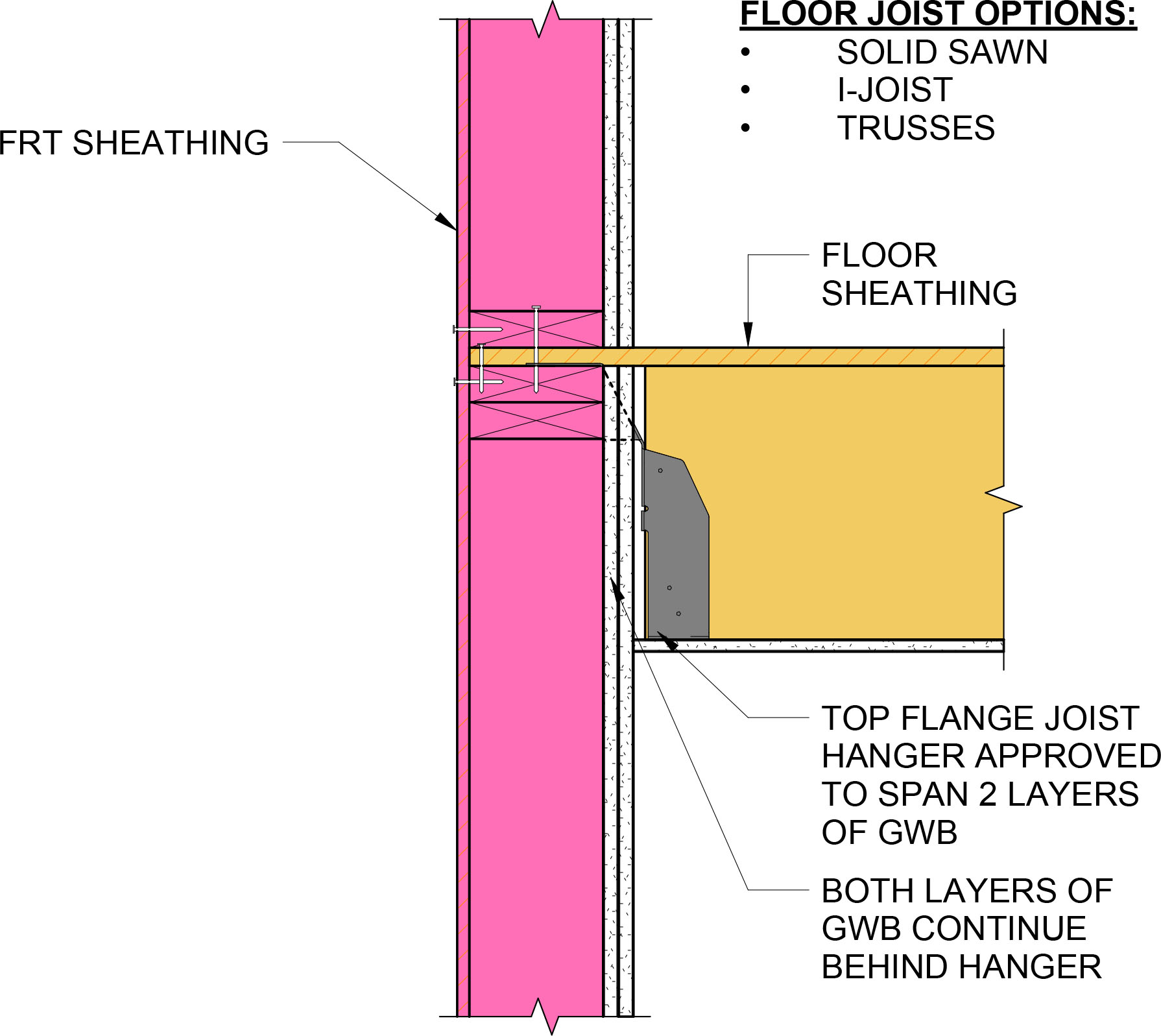

Figures 1a and 1b : Two commonly utilized assemblies of a semi-balloon framed exterior wall / floor intersection with continuous wall membrane to underside of floor sheathing above.

It is important to note that the fire-resistance continuity of the wall does not necessarily require the specific wall assembly to be continuous to the underside of the floor or roof such as with a semi-balloon framed wall (figure 1a). Instead, continuity can be maintained via wood blocking (including structural composite materials), rimboard, gypsum, or sheathing to meet the required fire-resistance of the wall based upon IBC table 601. This is common to platform framing (figure 1b) and the calculation of the FRR will be discussed in greater detail below.

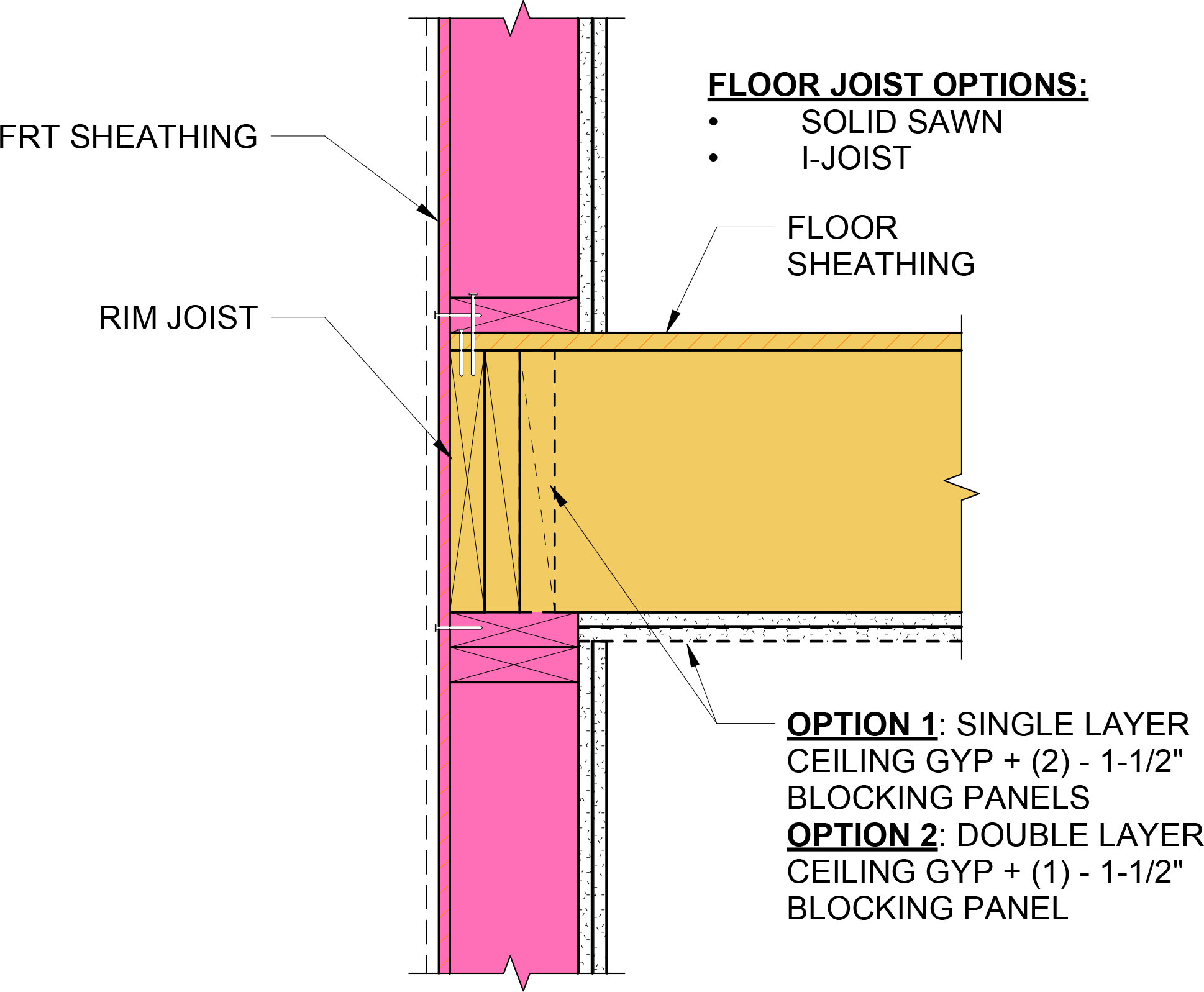

Figure 2: Traditional platform framing utilizing calculated fire resistance of blocking panels and ceiling membrane to maintain the required fire resistance rating of the exterior wall supporting elements within the floor assembly.

- IBC 705.7.1 – Floor Assemblies in Type III Construction

- This 2024 addition addresses the question of material and FRR requirements of floor elements that support exterior walls by clarifying the following:

- Floor assembly building elements within the plane of the exterior wall, including rim joists, rim boards, and blocking, do not have to be non-combustible or FRTW. Instead, they can be untreated wood, or any other material allowed by code, in accordance with interior building elements of Type III construction (Section 602.3).

- The FRR for the portion of the floor assembly that supports the exterior wall (e.g., rim boards) shall not be less than the fire-resistance rating of the exterior wall being supported. Clarifying language within Section 705.7.1 includes the contribution of the ceiling membrane toward the required minimum fire-resistance rating of the floor/ceiling assembly elements supporting the exterior wall.

To help address the implementation of this new language within the design and construction community, a committee of experts from the American Wood Council (AWC), WoodWorks and partner organizations investigated code requirements and testing completed for the floor-to-exterior wall configuration. Detailing strategies were developed which are both “framer friendly” and meet IBC requirements. The strategies and rationale behind them are included in the 2024 update of the AWC’s DCA 3 – Fire-Resistance-Rated Wood Floor and Wall Assemblies including fire resistance times for rim board, See Figures 1A, 1B, 1C and 2 within the document.

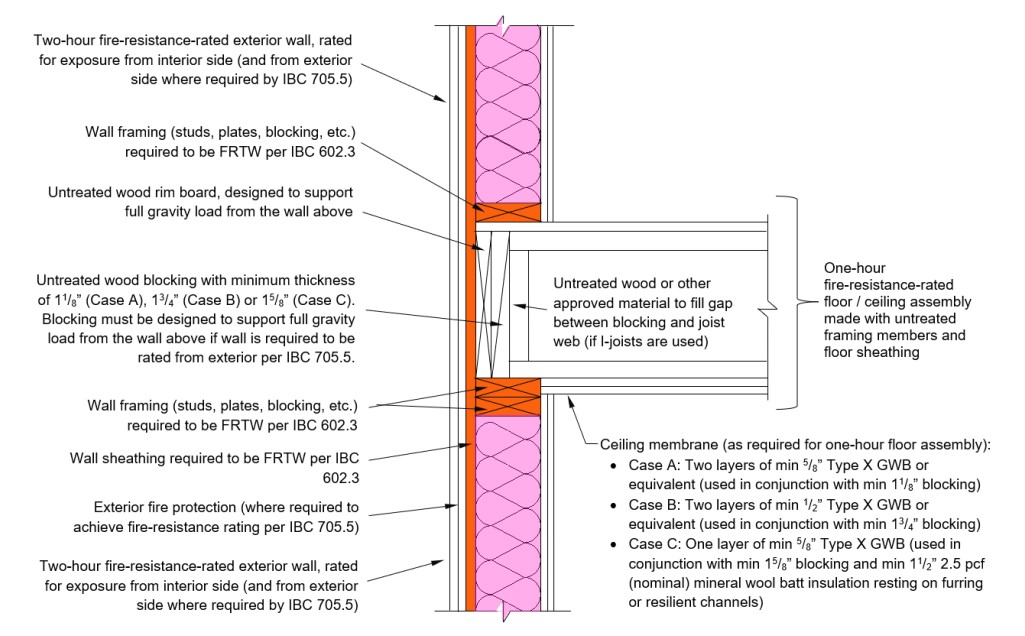

Figure 3: (from AWC DCA-3, Figure 1A): Example Detail for Type III-A exterior wall-floor intersection with rim board and blocking

(Courtesy of American Wood Council)

One example within the document, Figure 1A (shown above), illustrates the detail and rationale of how a 1-hour fire-rated floor assembly with ceiling membrane of Type X or Type C gypsum wallboard can be platform-framed on a 2-hour fire-rated wall. The required 2 hours of protection from within the room through the exterior wall is provided by a combination of the ceiling membrane, sacrificial wood blocking (in the depth of the floor) and a rim board at the end of the floor framing in the plane of the exterior wall. Additionally, DCA 3 notes that neither the sacrificial blocking in the wall, floor framing, nor floor sheathing that penetrates the exterior walls needs to be FRTW as these are simply extensions of the floor assembly, not members of the exterior wall. IBC only requires that exterior wall framing and sheathing be FRTW.

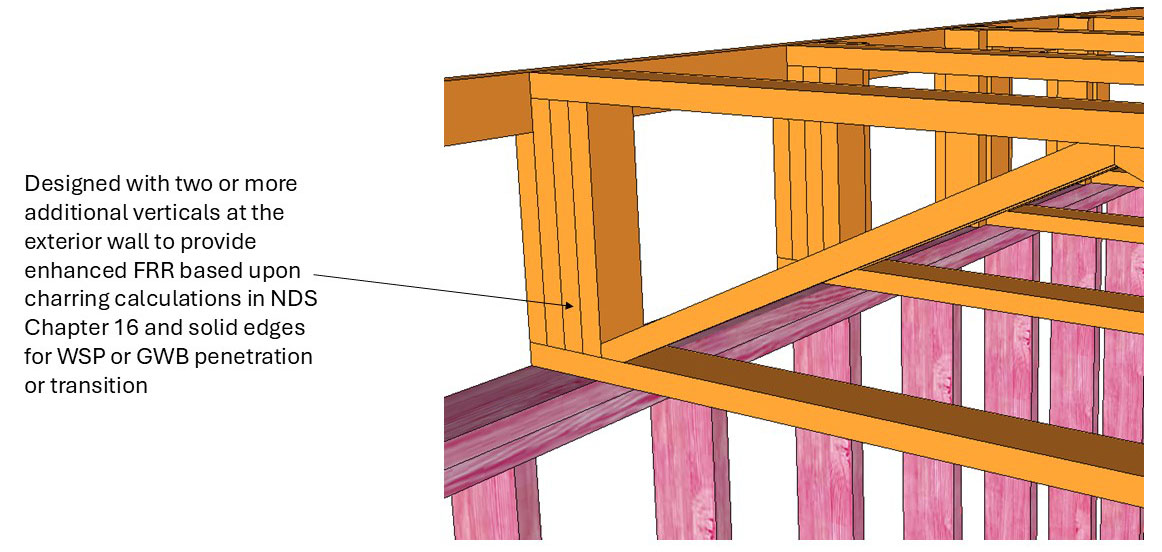

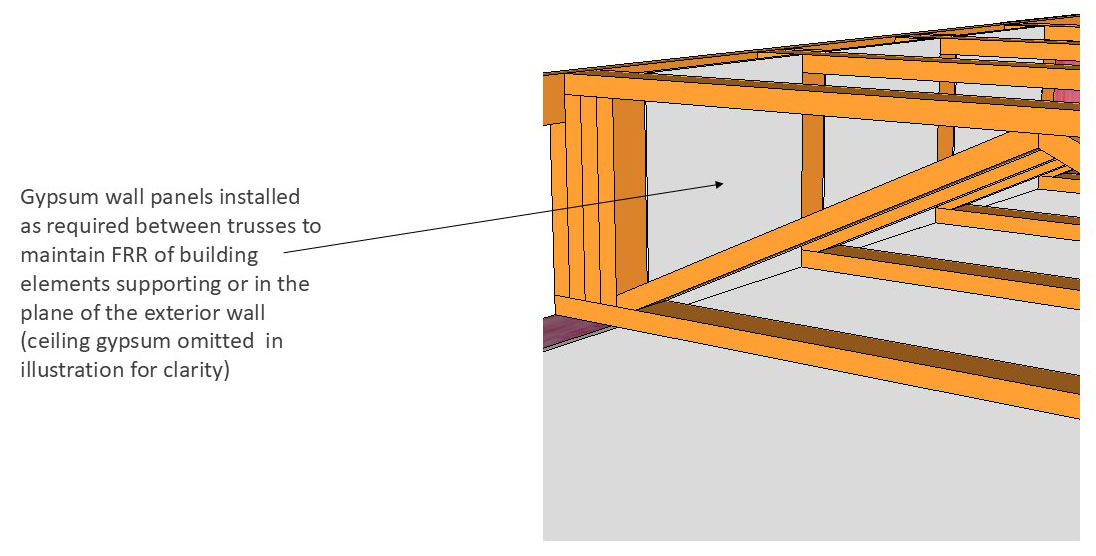

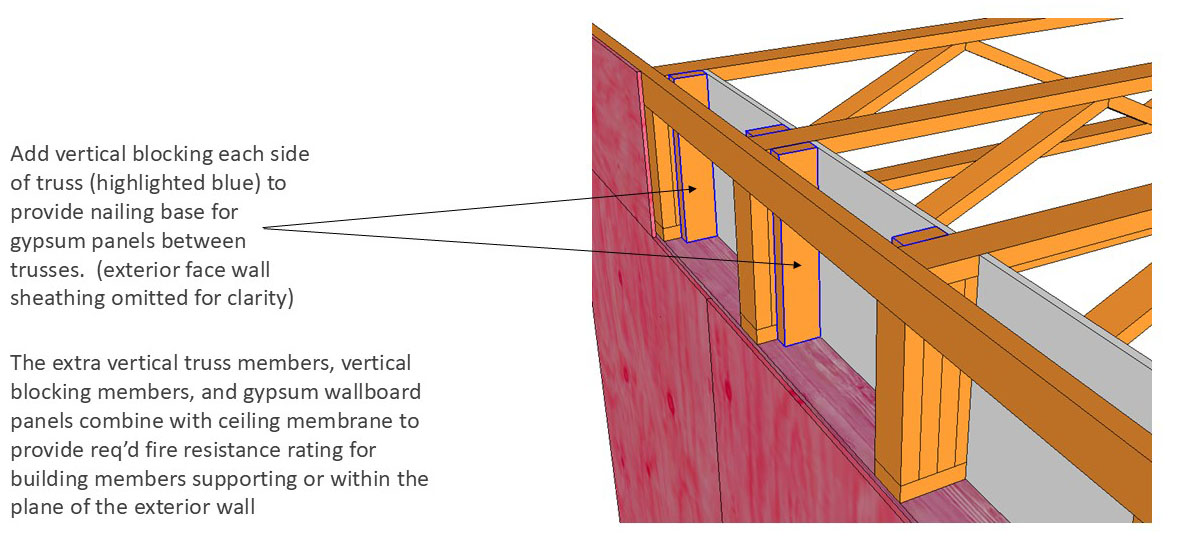

For typical joist system (solid sawn or I-Joists) blocking between the joists to maintain the fire-resistance continuity of the wall support is relatively easy to achieve, especially with 2×6 framed walls, which allow multiple pieces of blocking or rim to meet the necessary fire-resistance rating. However, for open-web floor trusses, which may not utilize a rim board on the exterior, designers often rely on the vertical elements located within the end of the truss for load transfer from the wall above to the wall below. In traditional platform framing these elements within the truss must maintain the fire-resistance rating of the exterior wall above to the exterior wall below. This can be achieved similarly to the methods described above by utilizing blocking and/or gypsum to maintain the continuity of the wall fire-resistance rating to the underside of the floor or roof deck above. Although many methods exist, one of the growing methods is to simply add additional vertical elements to the end of the truss and continue the inner wall gypsum to the underside of the sheathing above. Secondary framing between the plates provides both a nailing surface for the gypsum wall board and provides additional protection to the vertical truss members transferring wall load. For this example and other Type III plated floor truss options consult with your WoodWorks Regional Director or local truss provider on regional approaches and solutions.

Figure 4: Sectional view of platform wall framing with additional vertical elements located in the end of the truss.

Figure 5: isometric view of plated floor trusses with additional vertical elements located at the end of the truss

Figure 6: isometric view of plated floor trusses with additional vertical elements located at the end of the truss

Figure 7: isometric view of plated floor trusses with additional vertical elements and gypsum wall board installed continuous to the underside of the floor or roof sheathing above. Exterior face wall sheathing omitted for clarity.

For assistance with this issue on a project, contact your local WoodWorks Regional Director.