Expert Tips

Designing Mass Timber Floor Assemblies for Acoustics

With careful design and detailing, mass timber buildings can meet the acoustic performance expectations of most building types.

The growing availability and code acceptance of mass timber—i.e., large solid wood panel products such as cross-laminated timber (CLT) and nail-laminated timber (NLT)—for floor, wall and roof construction has given designers a low-carbon alternative to steel, concrete, and masonry for many applications. However, the use of mass timber in multi-family and commercial buildings presents unique acoustic challenges.

While laboratory measurements of the impact and airborne sound isolation of traditional building assemblies such as light wood-frame, steel and concrete are widely available, fewer resources exist that quantify the acoustic performance of mass timber assemblies. Additionally, one of the most desired aspects of mass timber construction is the ability to leave a building’s structure exposed as finish, which creates the need for asymmetric assemblies. With careful design and detailing, mass timber buildings can meet the acoustic performance expectations of most building types.

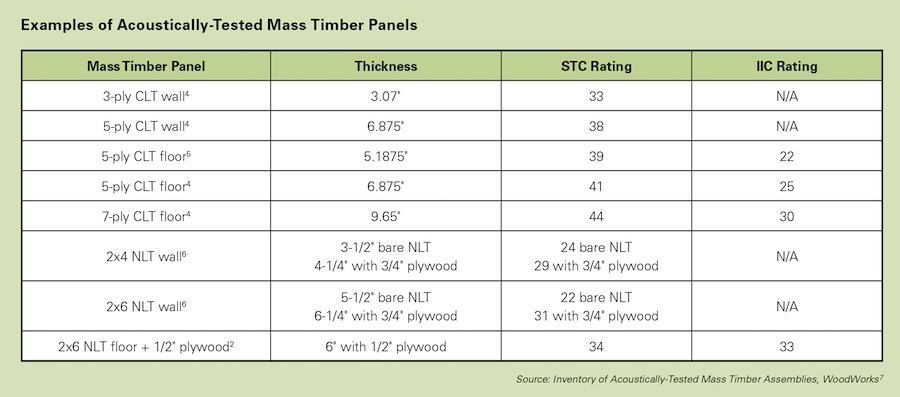

Bare mass timber floor/ceiling or wall assemblies are seldom used, in large part due to inadequate acoustical performance. For example, a 5-ply CLT floor with a thickness of 6.875″ has an STC rating of 41 and an IIC rating of 25. As such, components are typically added to mass timber assemblies to improve their acoustics. The table below shows acoustical properties of bare mass timber panels.

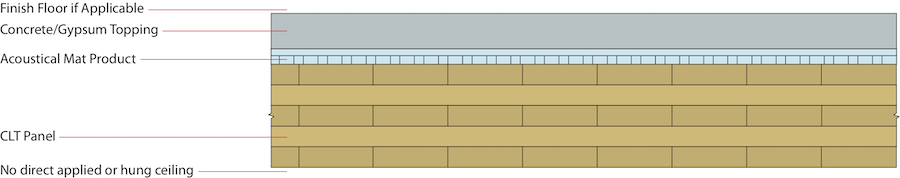

In floor/ceiling applications, owners and design teams often want to expose the ceiling side of mass timber panels for aesthetic reasons, which means that any acoustical components must be installed on top of the assembly. This is one of the main acoustical design distinctions between light wood-frame floor/ceiling assemblies and mass timber floor/ceiling assemblies. In light-frame construction, acoustical components are typically included above, within and below the assembly—e.g., underlayment and/or concrete topping above the framing, batt insulation within the depth of the framing, and resilient channels and gypsum ceiling board underneath.

There are three main ways to improve an assembly’s acoustical performance:

- Add mass

- Add noise barriers

- Add decouplers

One of the characteristics of mass timber is that it has a high strength-to-weight ratio; therefore, when compared to other panel and slab-type construction materials, it weighs significantly less. This reduces building mass, which is beneficial in terms of lower seismic forces, smaller foundation requirements, and soil improvement measures such as pilings or piers. However, with acoustics, more mass typically means better noise control. For comparison, a typical 6″-thick concrete slab weighs approximately 80 pounds per square foot (psf) and has an STC rating of 53 while a ~7″-thick CLT panel weighs about 18 psf and has an STC of 41. Due to the lack of mass inherent in the mass timber panel, a common way to improve acoustical performance is to add a poured concrete or gypsum-based topping layer, usually in the range of 1-3″ thick.

Decouplers are products that decouple, or break direct connections between, finishes on one side of an assembly and the other. This reduces the amount of noise that can directly travel through finish to structure to finish. Common examples in light wood-frame construction include resilient channels and air spaces. In mass timber floor/ceiling systems, the most common decoupling products are underlayments and mats placed between the mass timber panel and concrete or gypsum-based topping. The type and thickness of material varies by product line and manufacturer, but the purpose is the same: to break the direct connection between structure/ceiling finish (the mass timber panel) and the top side finish (topping and/or finish floor). Using this combination of materials—concrete/gypsum topping, acoustical mat and mass timber panel—is common and many examples of acoustically-tested assemblies exist for this buildup.

For information on these tested assemblies, as well as other design considerations for acoustics, see the WoodWorks paper Acoustics and Mass Timber: Room-to-Room Noise Control and our Inventory of Acoustically-Tested Mass Timber Assemblies.