Expert Tips

Shaft Wall Requirements for Tall Mass Timber Buildings

In-depth look at shaft enclosure requirements, including allowable materials, noncombustible protection, fire-resistance ratings, and other considerations.

The 2021 International Building Code (IBC) introduced three new construction types—Type IV-A, IV-B and IV-C—which allow tall mass timber buildings. For details on the new types and their requirements, see the WoodWorks paper, Tall Wood Buildings in the 2021 IBC – Up to 18 Stories of Mass Timber. This paper builds on that document with an in-depth look at the requirements for shaft walls, including when and where wood can be used.

Shaft Enclosure Requirements in the 2021 IBC

A shaft is defined in Section 202 of the 2021 IBC as an enclosed space extending through one or more stories of a building, connecting vertical openings in successive floors, or floors and roof. Therefore, shaft enclosure requirements apply to stairs, elevators, and mechanical/electrical/plumbing (MEP) chases in multi-story buildings. While these applications may be similar in their fire design requirements, they tend to differ in terms of their assemblies, detailing, and construction constraints.

Shaft enclosures are specifically addressed in IBC Section 713. However, because shaft enclosure walls must be constructed as fire barriers per Section 713.2, many shaft wall requirements reference provisions for fire barriers found in Section 707.

Allowable Shaft Wall Materials

Provisions addressing materials permitted in shaft wall construction can be found in both the shaft enclosures section (713.3) and fire barriers section (707.2) of the code. These sections state that fire barriers can be constructed of any material permitted by the building’s type of construction. One of the baseline requirements for tall wood structures utilizing construction Types IV-A, IV-B or IV-C is that they be constructed of either mass timber or noncombustible materials (or a combination thereof).

A relatively new category of wood products, mass timber can encompass well known and widely used products such as glued-laminated timber (glulam) and nail-laminated timber (NLT), as well as newer panelized products such as cross-laminated timber (CLT). The definition of mass timber adopted for the 2021 IBC is:

Structural elements of Type IV construction primarily of solid, built-up, panelized or engineered wood products that meet minimum cross-section dimensions of Type IV construction.

This means that mass timber may be used for shaft wall construction in tall wood construction Types IV-A, IV-B and IV-C, with one exception. Section 602.4 of the 2021 IBC notes the following with regard to shaft walls in buildings taller than 12 stories or 180 feet:

In buildings of Type IV-A, B, and C, construction with an occupied floor located more than 75 feet above the lowest level of fire department access, up to and including 12 stories or 180 feet above grade plane, mass timber interior exit and elevator hoistway enclosures shall be protected in accordance with Section 602.4.1.2. In buildings greater than 12 stories or 180 feet above grade plane, interior exit and elevator hoistway enclosures shall be constructed of noncombustible materials.

Following these code provisions, mass timber may be used as a shaft enclosure material in tall wood buildings—except Type IV-A buildings that exceed 12 stories or 180 feet.

Noncombustible Protection of Mass Timber Shaft Walls

When used as shaft walls in Type IV-B or IV-C buildings (or IV-A buildings that do not exceed 12 stories or 180 feet) mass timber must be covered on both faces with noncombustible materials, as noted in the definitions of these construction types:

Shafts in Type IV-A:

602.4.1.6 Shafts. Shafts shall be permitted in accordance with Sections 713 and Section 718. Both the shaft side and room side of mass timber elements shall be protected in accordance with Section 602.4.1.2.

Shafts in Type IV-B:

602.4.2.6 Shafts. Shafts shall be permitted in accordance with Section 713 and Section 718. Both the shaft side and room side of mass timber elements shall be protected in accordance with Section 602.4.1.2.

Mass timber shafts in IV-A and IV-B must be protected with noncombustible materials as noted in the code sections above. Protection of mass timber shafts in these buildings must also comply with section 602.4.1.2, noted below. Protection time refers to contribution to the fire-resistance rating (FRR).

602.4.1.2 Interior protection. Interior faces of all mass timber elements, including the inside faces of exterior mass timber walls and mass timber roofs, shall be protected with materials complying with Section 703.5.

602.4.1.2.1 Protection time. Noncombustible protection shall contribute a time equal to or greater than times assigned in Table 722.7.1(a), but not less than 80 minutes. The use of materials and their respective protection contributions listed in Table 722.7.1(b) shall be permitted to be used for compliance with Section 722.7.1.

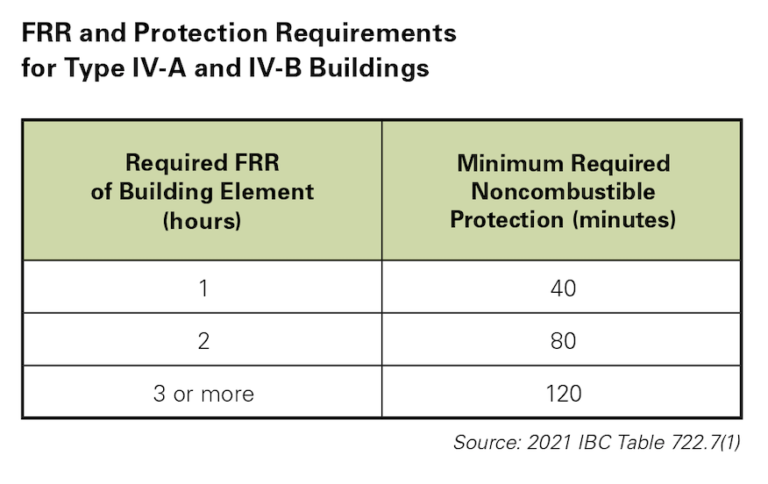

Table 722.7(1) notes that noncombustible protection must provide two thirds of the required FRR of an assembly or element:

Any noncombustible material intended to be used as protection of mass timber elements can be tested following the procedure outlined in IBC Section 703.8 to determine its contribution to the FRR. However, two prescriptive options are presented in IBC 2021 Section 722.7.1 and, as noted in 602.4.1.2.1, may be used to provide the required contribution of noncombustible shaft wall covering. Determined through testing, the prescriptive options listed are 25 minutes for each layer of 1/2-inch Type X gypsum board and 40 minutes for each layer of 5/8-inch Type X gypsum board. As such, a common solution would be one layer of 5/8-inch Type X gypsum for each hour of FRR required, noting that a minimum of 80 minutes of noncombustible protection is required for construction Types IV-A and IV-B.

Mass timber shaft walls in Type IV-C buildings only require 40 minutes of noncombustible covering; a common solution is one layer of 5/8-inch Type X gypsum.

Shafts in Type IV-C:

602.4.3.6 Shafts. Shafts shall be permitted in accordance with Section 713 and Section 718. Shafts and elevator hoistway and interior exit stairway enclosures shall be protected with noncombustible protection with a minimum assigned time of 40 minutes as determined in Section 722.7.1(a), on both the inside of the shaft and the outside of the shaft.

Shaft Wall Fire-Resistance Ratings

FRRs are defined in IBC Section 202 as the period of time a building element, component or assembly maintains the ability to confine a fire, continues to perform a given structural function or both. An important nuance is the difference between fire confinement and the ability to continue providing structural support. Fire resistance-rated walls may be required to do one or the other or both depending on the wall assembly and its application. Shaft enclosures are only one type of fire barrier application, and fire barriers are only one type of fire resistance-rated wall assembly. Requirements for these assemblies often differ from exterior wall, fire wall, and fire partition assemblies—specifically requirements relating to continuity, structural support/stability, and penetrations.

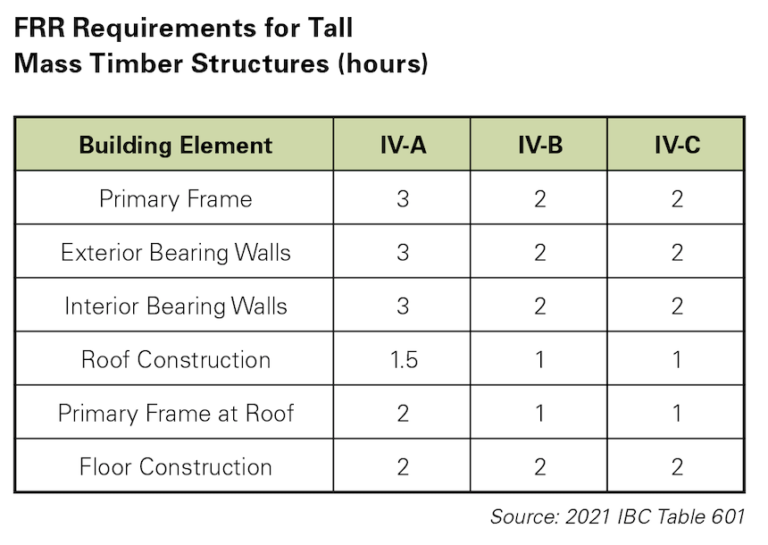

As noted in IBC Section 713.4, shaft enclosures are required to have an FRR of not less than 2 hours when connecting four or more stories. An FRR of not less than 1 hour is required for shaft enclosures connecting less than four stories. Shaft enclosures are also required to have an FRR not less than the floor assembly penetrated. In all three tall mass timber construction types, the required floor FRR is 2 hours, indicating that shaft enclosures in any of the three new types will require a 2-hour rating (even if the building is less than four stories tall). The only exception to this is shaft walls that are also bearing walls in Type IV-A construction, since these walls would require a 3-hour FRR per IBC Table 601:

Contribution of Mass Timber to Shaft Wall FRR

As noted, mass timber shaft walls are required to have noncombustible protection: 80 minutes for Types IV-A and IV-B (or 120 minutes for load-bearing shaft walls in Type IV-A), and 40 minutes for Type IV-C. The remaining time required to meet the full 2-hour FRR (or 3-hour FRR for load-bearing shaft walls in Type IV-A) must be demonstrated through the inherent fire resistance of the mass timber element, or by other means approved by the building official.

For example, a mass timber shaft wall in a Type IV-B building requires a 2-hour FRR, 80 minutes of which would be provided by noncombustible protection (likely 2 layers of 5/8-inch Type X gypsum), and the remaining 40 minutes by the mass timber. Similarly, a mass timber shaft wall in a Type IV-C building would need to demonstrate 80 minutes of resistance via the mass timber, and the remaining 40 minutes through the noncombustible covering. Although this design route of arriving at the total FRR through a combination of noncombustible covering and mass timber may prove most cost effective, an alternative that may be worth exploring is to achieve the full 2-hour FRR via noncombustible layers (i.e., three layers of 5/8-inch Type X gypsum). Although there is added cost in the gypsum, it may be possible to reduce the thickness of the mass timber element resulting in other cost savings. Note that minimum wall thicknesses for Type IV structures shown in IBC Section 2304.11 must still be met, and structural loads on the mass timber element may also further dictate wall thickness.

IBC Section 703.2 provides options for demonstrating FRRs for mass timber. Ratings must be determined through testing in accordance with ASTM E 119 (or UL 263) or via one of six alternatives listed in IBC Section 703.3.

Item 3 of IBC Section 703.3, which permits the use of calculations in accordance with Section 722, is frequently used. IBC Section 722.1 states: The calculated fire resistance of exposed wood members and wood decking shall be permitted in accordance with Chapter 16 of ANSI/AWC National Design Specification® for Wood Construction (NDS®). Chapter 16 of the NDS can be used to calculate up to a 2-hour FRR for a variety of exposed wood members including solid sawn, glulam, structural composite lumber, and CLT.

Successful fire tests have been completed on numerous mass timber elements and assemblies, achieving fire-resistance ratings of 3 hours or more. Additional tests by manufacturers and others are ongoing. For additional information on both the calculation-based method and the ASTM E119 testing method of demonstrating the FRR of mass timber elements, see the WoodWorks publication Fire Design of Mass Timber Members and its accompanying Inventory of Fire Resistance-Tested Mass Timber Assemblies & Penetrations.

Other Considerations

In addition to the FRR and contribution of noncombustible coverings, designers must consider factors such as acoustics and structural loads when choosing shaft wall assemblies for tall wood buildings. For information on the acoustical design of mass timber wall assemblies, see the WoodWorks publication Acoustics and Mass Timber: Room-to-Room Noise Control and its accompanying Inventory of Acoustically-Tested Mass Timber Assemblies.

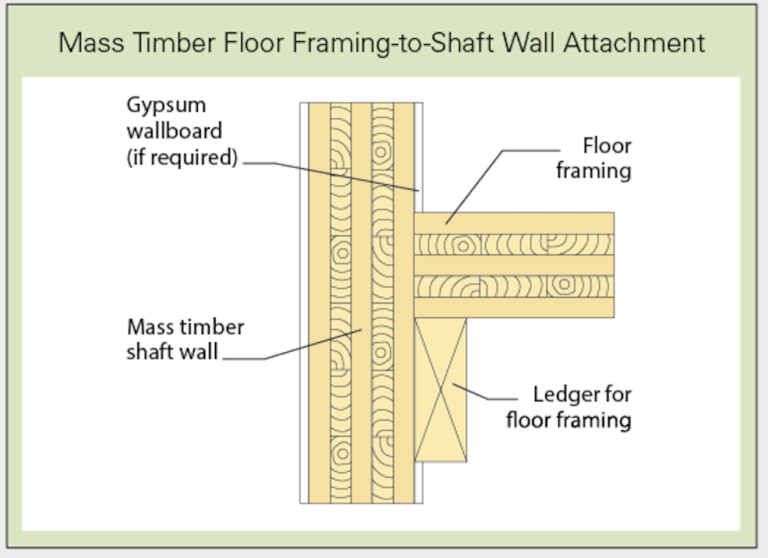

Detailing floor-to-shaft and roof-to-shaft wall intersections also requires consideration of these factors, and it is often beneficial to discuss proposed details with the Authority Having Jurisdiction (AHJ) early in design. Some mass timber structures have utilized mass timber shaft walls that are multiple stories per lift, resulting in adjacent mass timber floor panels being supported by the shaft walls by way of a ledger. This approach is shown in the detail below. Other projects have used a platform-frame approach, with shaft walls lifted in one-story increments and adjacent floor panels bearing on the walls. Speed of construction, structural loading, cumulative shrinkage and crushing potential, and fire barrier continuity are all factors that will help inform the detail selection.