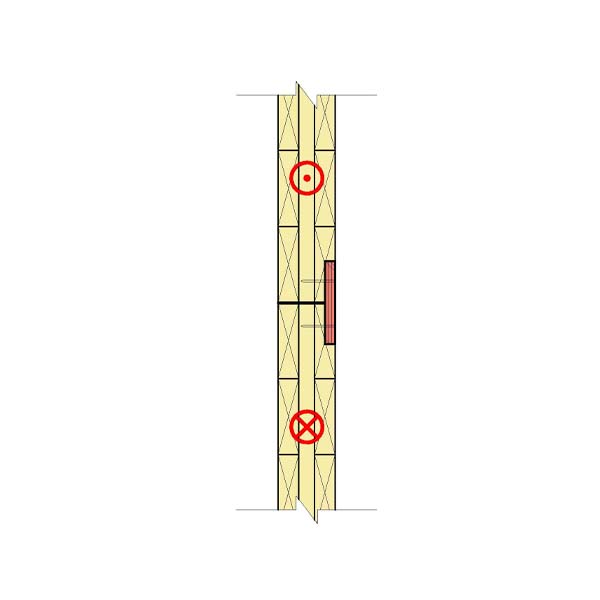

Panels Connect with Single Surface Spline

Adjacent floor panels with routed surfaces are butted together. A plywood spline is fastened to both panels using partially-threaded screws or nails.

Adjacent floor panels with routed surfaces are butted together. A plywood spline is fastened to both panels using partially-threaded screws or nails.

Purpose: Transfer of in-plane shear along the panel-to-panel joint.

Capacity of connection is controlled by shear capacity of dowel-type fasteners.