Expert Tips

Sealants and Adhesives at Intersecting Mass Timber Members

Code compliance, design impacts, and types of member and assembly intersections in mass timber buildings

This article references the 2024 International Building Code (IBC).

A benefit of designing with mass timber is the ability to provide fire-resistance-rated construction while keeping the structure exposed as the architectural finish. This fire resistance relies on a char layer that forms when exposed to fire; the large thickness and size of the mass timber members allow them to char on the outside, while core sections of the elements remain cold and retain their structural integrity. What happens when there are joints between adjacent mass timber members? If the members are tight fitting, such as at the corner of a cross-laminated timber (CLT) shaft enclosure where two CLT shaft walls meet, is this adequate for fire performance, or are additional sealants or adhesives required?

Types of Member and Assembly Intersections

First, it is important to define the different types of member and assembly intersections that may exist in a mass timber building. Section 715 of the IBC covers the requirements for joints and voids. However, a joint is not simply the intersection of two members; a joint is defined in IBC as having a physical gap or separation between adjacent assemblies created due to building tolerances or is designed to allow independent movement of the building. Examples include the head of a non-load-bearing partition wall and a seismic separation between portions of a building.

In one example, a mass timber shaft wall is being designed, and the corner where two walls intersect is under consideration.

Shaft enclosures are required to be designed as fire barriers per IBC 713.2, which references section 707. In some instances, confusion comes from looking at IBC Section 707.8, which states: “Joints made in or between fire barriers, and joints made at the intersection of fire barriers with the underside of a fire resistance-rated floor or roof sheathing, slab or deck above, and with other fire-resistance-rated wall assemblies shall comply with section 715.”

Compliance with Section 715 requires that the “joint” be protected with a material that meets ASTM E1966 or Underwriters Laboratory (UL) 2079. (See IBC Section 715.3.1.) However, the “joints” referenced in Sections 707.8 and 715 are those where a linear gap exists, such as between the top of the fire barrier and underside of the floor sheathing, that would allow free passage of fire. Other examples include a seismic isolation joint or an expansion joint. Code commentary in IBC Sections 707.8 and 715.1 provide additional clarification.

In another example, the two mass timber shaft walls that intersect (i.e., at wall corners) do not create a joint since no physical gap or separation between structural members is created.

Although a “joint or void” may not be present by definition of the code, there is one more important section to consider when detailing the intersections. Section 703.7 of the IBC includes a new requirement for the use of sealants or adhesives at abutting panel edges, as well as at the intersection of mass timber elements and fire-rated elements of construction Types IV-A, IV-B, and IV-C:

In buildings of Types IV-A, IV-B and IV-C construction, sealant or adhesive shall be provided to resist the passage of air in the following locations:

- At abutting edges and intersections of mass timber building elements required to be fire-resistance rated.

- At abutting intersections of mass timber building elements and building elements of other materials where both are required to be fire-resistance rated.

Sealants shall meet the requirements of ASTM C920. Adhesives shall meet the requirements of ASTM D3498.

Exception: Sealants or adhesives need not be provided where they are not a required component of a tested fire-resistance-rated assembly

The IBC commentary lends helpful insight into this code change, as well as the topic as a whole. Here is an excerpt from the commentary:

The requirement to provide sealants or adhesive at intersections of fire-resistance-rated mass timber elements addresses the potential for airflow to carry hot gases and other products of combustion into gaps at the connections between mass timber elements.

Construction adhesive or other sealants can be used to prevent air flow. Where a wall or horizontal assembly serves as the separation between two atmospheres, a fire creates differential pressure where heated gases raise the pressure and work to drive fire and hot gases through the structure. Voids that are not properly sealed can serve as a conduit for air movement during a fire, so abutting edges and intersections are recommended to be sealed.

This new code section first appeared in the 2021 IBC as part of a package of 17 code change proposals submitted by the ICC Tall Wood Building (TWB) Ad Hoc Committee. The ICC TWB Ad Hoc Committee addressed the topic of sealants, adhesives, and intersecting mass timber members in their proposal package, providing a reason statement to help create the code commentary above. The reason statement also noted that the “U.S. CLT manual recommends a bead of construction adhesive [at abutting panels]. Mass timber has inherent properties of fire resistance, serving both to provide structural fire resistance and to safeguard against the spread of fire and smoke within a building or the spread of fire between structures. When mass timber panels are connected together, fire tests have demonstrated that it is important for the abutting edges and intersection in the plane of and between the different planes of the panels that form a separation to be sealed. The structures tested as part of the fire tests supporting this submittal were constructed with this sealing”.

The fire tests referenced by the Ad Hoc Committee in this reason statement are the ATF compartment fire tests. More information on those tests is available here.

Additionally, section 703.7 of the ICC/AWC document Mass Timber Buildings and the IBC provides further discussion on this topic.

Application in Mass Timber Buildings

After understanding the above code provisions, two questions naturally arise:

- Are adhesives or sealants also required at the intersection of mass timber elements in construction types other than IV-A, IV-B, and IV-C?

- In lieu of using adhesives and sealants, can a monolithic topping slab poured over a mass timber floor or roof assembly be used to prevent the passage of airflow?

Answers to these questions are addressed in the sections that follow.

Question: Are adhesives or sealants also required at the intersection of mass timber elements in construction types other than IV-A, IV-B, and IV-C?

Answer: There is no explicit IBC requirement for the use of adhesives or sealants at the intersection of mass timber elements in other construction types, such as Type III-A, III-B, IV-HT, V-A, or V-B. However, that does not necessarily mean that adhesives or sealants are not necessary to ensure the intended function of assemblies, which must provide fire or smoke containment. It is important to understand the code’s intent for fire-resistance-rated assemblies and the general concepts of compartmentalization.

The intent of IBC Section 703.7 is to prevent the passage of air through intersections that aren’t otherwise required to have a fire-resistant joint system, as defined in the code. Under the IBC, for construction types IV-A, IV-B and IV-C, there is an explicit requirement that adhesives/sealants be present (unless an assembly is used which was fire tested without them). Given the function of these adhesives/sealants, and the fact that these adhesives/sealants are not designed to withstand high temperatures, they should be placed in a location where they will not be exposed to high temperatures (i.e., closer to the unexposed side of the assembly or in the middle of an intersection potentially exposed on either side).

The 2024 Fire Design Specification for Wood Construction (FDS), produced by the American Wood Council, provides insights and data on the fire performance and design of light-frame wood and mass timber buildings. Section 3.2.3 of the document discusses the design of abutting edges and intersections for char penetration. It is common practice to have a 1/16” gap between adjacent mass timber floor panels for tolerance purposes. To address gaps such as this, or other member intersections, the FDS notes the following:

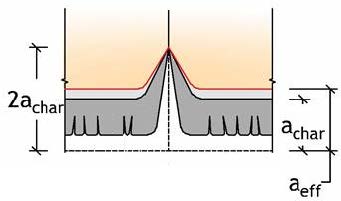

3.2.3.1 For exposed wood members with intersections or abutting edges that are protected on the exposed side with an approved fire-resistant joint system in accordance with 2.5.1.3, the char front shall be assumed to penetrate between wood members a distance equal to achar.

3.2.3.2 For exposed wood members with intersections or abutting edges that are in contact or have a gap less than or equal to 1/8 inch, the char front shall be assumed to penetrate between wood members a distance equal to 2achar (see Figure 3.1), provided that air flow through the gap does not occur. Air flow through the gap is permitted to be neglected where one of the following occurs:

- The intersection is detailed to prevent burn-through in accordance with 3.7.

- Draftstopping material as listed in 2.5.3.1, excluding fiberglass and mineral wool batts, is installed on the unexposed side of the assembly.

- Adhesives or sealants meeting ASTM C920 or ASTM D3498 are applied in the gap on the unexposed side of the assembly.

- The intersection occurs entirely within a single compartment such that the gap does not provide for air passage between compartments.

3.2.3.3 For exposed wood members with intersections or abutting edges that are initially in contact or have a gap less than or equal to 1/8 inch but where airflow between members cannot be prevented, wood surfaces within the intersection or abutting edge shall be assumed to be fully exposed to the fire for the full depth of the intersection or abutting edge.

Figure 3-1. Char penetration at abutting wood members that are unbonded

Courtesy of the American Wood Council

Using the above information from the FDS, not only does the location of intersecting or abutting members become a question of whether it can meet the code’s intention for the purpose of preventing airflow, it also becomes a question of char design of the members themselves, evaluating the advancement of char between members. If the intersection has a gap large enough to allow the passage of airflow, or if the gap is relatively small but detailed in such a manner that the passage of airflow can still occur, the members at the intersection may require additional analysis to evaluate the effects of char penetration on member capacity. Option three presented in FDS Section 3.2.3.2 is similar to the options presented in IBC 703.7, but it is not the only option. For the purposes of both preventing the passage of airflow and appropriately designing the char depth and char penetration at abutting and intersecting mass timber members and assemblies, it is good practice to include adhesives or sealants at these locations unless the project was specifically designed for the omission of these items.

Question: In lieu of using adhesives and sealants, can a monolithic topping slab poured over a mass timber floor or roof assembly be used to prevent the passage of airflow?

Answer: A monolithic topping slab is common practice in mass timber floor and in some cases roof assemblies. This topping is often non-structural poured over an acoustic mat, and its main purposes are to add mass to the assembly thereby aiding its acoustic performance, and to add a durable walking surface or a surface to which a finish floor can be attached. The topping slab is usually normal weight concrete, lightweight concrete or gypsum based. Common thicknesses range from 1-3”.

While poured cementitious topping slab is not listed in the 2024 FDS Section 2.5.3.1 or 2024 IBC 718.3.1 as an explicitly recognized draftstop material, many mass timber floor assemblies have successfully passed fire-resistance rating tests using such cementitious toppings on top of mass timber panels. The IBC does recognize that “other approved materials” can be used at draftstopping, and based numerous successful fire resistance rating tests, it is reasonable to propose that concrete topping layer provides adequate draftstopping behind intersections in mass timber elements below. If particular details are not part of a tested assembly, the approval of proposing such details is subject to approval at the Authority Having Jurisdiction (AHJ).