Expert Tips

Mass Timber Moisture Management for Construction

Strategies for managing the unique moisture risks of mass timber building projects and developing a moisture management plan to implement during construction

Mass timber projects have unique considerations for managing moisture. Although mass timber can, and usually will, get wet during construction, problems can be avoided with proper planning and the right moisture control strategies. The most effective approach begins with planning during the project design phase (well before the mass timber arrives on site) and continues throughout construction.

Why Moisture Management Matters

Mass timber can safely absorb and dry some amount of moisture, but risks occur if the wood elements cannot readily dry due to deep wetting, if water becomes trapped at mass timber interfaces such as below concrete floor toppings or roofing membranes, or if the wood experiences repeated wetting and drying cycles.

The five main reasons to keep mass timber as dry as possible are:

- Schedule delays and additional costs. If mass timber elements get wet, additionaltime, labor, and replacement materials may be necessary to dry, replace, or remediate the area. This added time may cause schedule delays and add unexpected costs to the project budget.

- Stains. Exposed timber is often a design feature. Not only must wet wood be properly dried, it may need cleaning/sanding and refinishing to remove water stains. This can result in added labor and delays and lead to visual imperfections.

- Extensive shrinkage and swelling. Repeated cycles of high moisture (wetting) and drying cause repeated shrinking and swelling that may cause excessive checking in the wood. Swelling can also put added strain on structural attachments and fail fasteners.

- Microbial growth. Exposure to sustained elevated moisture, especially at concealed locations or between joints or layers of assemblies, can result in fungal and bacterial growth on and in the wood.

- Decay and structural damage. If moisture is trapped within the wood and unable to dry, it can lead to decay, delamination, and corrosion of connections and fasteners, causing a loss of structural strength.

Each mass timber project will typically have some level of tolerance to schedule delays, added cost, and staining. However, significant movement due to excessive shrinking and swelling, microbial growth, and damage are intolerable. Intolerable risks can occur when project teams do not understand the potential severity of moisture risks, are not adequately protecting the mass timber from moisture, and/or do not know how to identify higher-risk conditions such as trapped moisture.

Trapped moisture presents a moisture-related risk to any mass timber project because the thickness of panels limits them from drying out. Moisture can penetrate deep into the mass timber and become trapped within the pore structure of the wood, within the adhesives, at gaps between the wood elements, at joints and interfaces between panels and connections, and at other locations. The end grain of mass timber absorbs water more quickly than its surface, so the panel edges and penetrations are more susceptible to moisture-related risks.

Moisture Content

Moisture content is the percent of a material’s mass that is water. Wood naturally loses and gains moisture to reach an equilibrium with the moisture of its environment, so fluctuations in moisture content are expected. To manage the exposure risks, moisture content must be kept within an appropriate range. Protecting the mass timber from large and rapid changes in moisture content can also limit checking.

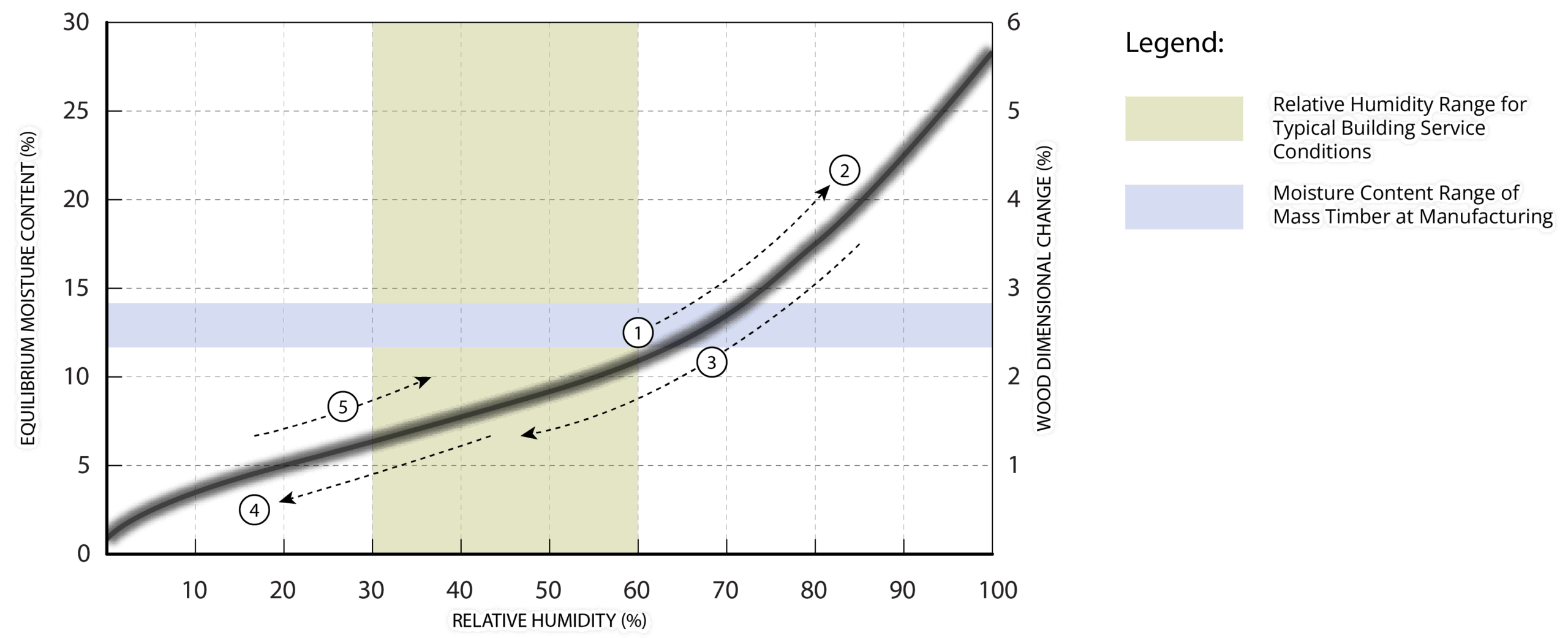

When mass timber products are fabricated, their moisture content is typically in the range of 12% to 14%. Once the wood is on site and exposed to relative humidity and precipitation, it can climb to 15% to 20% under normal conditions. This number could climb higher than 30% at areas exposed to wetting. Once in service, the wood will generally dry to 5% to 10% moisture content depending on the ambient relative humidity. Figure 1 illustrates these changes.

FIGURE 1: Generic sorption isotherm for wood at 70°F (21°C) showing that the moisture content, and resulting dimensional change, of mass timber throughout construction and service life can be described as: (1) mass timber at manufacturing and delivery to site; (2) wetting and expansion of the mass timber during construction; (3) drying and shrinkage of mass timber to reach typical building service conditions; (4) further potential for mass timber drying and shrinkage in lower than normal relative humidity service conditions; (5) stabilization of the interior relative humidity that minimizes the moisture content changes and resulting dimensional changes of the mass timber.

Adapted from the Wood Handbook: Wood as an engineering material1

The typical equilibrium moisture content of wood materials within the building enclosure during occupancy ranges from 7% to 12% (approximately 30% to 60% relative humidity) depending on the interior relative humidity conditions. This means wood panels may experience only minor changes in moisture content from fabrication to typical building service conditions, depending on the indoor and outdoor conditions. However, if the panels become wet during construction or the in-service conditions are atypical—such as lower or higher than normal indoor humidity conditions or large fluctuations in humidity—it may be necessary to regulate the indoor relative humidity over a longer period during the building commissioning phase. This regulation will prevent rapid changes to the moisture content that could lead to dimensional changes, checking, and warping in the wood panels.

Identifying Moisture Risk Factors

Effective moisture protection approaches for mass timber projects can be determined by first looking at the risk factors and then choosing from proven strategies to mitigate those risks.

Moisture exposure considerations:

- What is the climate and expected construction-phase precipitation at the project site?

- What is the expected duration of time between the installation of floors (i.e., when is each floor protected from rainwater above)?

- When will the enclosure assemblies be closed in or dried in to protect the structure from moisture exposure?

Protection considerations for all construction phases:

- What is the transportation distance between the mass timber factory and project site, and how will the mass timber elements be protected while in transit?

- Will the mass timber elements be stored on site prior to installation, and how will they be protected during storage?

- What strategies will be used to protect the mass timber, such as protective membranes, tenting, or construction barriers?

Assembly considerations:

- Are there any concrete or gypsum-based toppings on the floors or roofs that will increase the risk of trapped moisture?

- Can layers of the final assembly be used as temporary roofing during construction?

- Which mass timber elements will be left visually exposed (i.e., used as the architectural finish) and what is the tolerance to staining?

- Will moisture-sensitive fire protection such as gypsum sheathing be installed to encapsulate some mass timber elements?

- Does the project include steel elements in contact with wood that could cause staining?

By evaluating these questions, the project team can begin to identify which mass timber elements are at a higher risk of being exposed to moisture and impacted by moisture exposure outcomes. Appropriate moisture control strategies can then be put in place.

Bear in mind that the risk of moisture exposure can never be removed entirely but can be mitigated with protection and active management that is appropriate for the moisture exposure. Typically, it is recommended that low, moderate, and high moisture exposures be managed with protection types having low, moderate, and high protection robustness, respectively. The cost of protection and related efforts can then be balanced with active water management efforts on site.

As an example, less protection may result in increased moisture-related risks that will require more active on-site management. Although this is a feasible management approach, the increased labor needed to actively manage water can be more costly and time-consuming than passive protection approaches.

Creating a Moisture Management Plan

After identifying risk factors, the team can begin planning for moisture management prior to the construction phase. Mass timber buildings require a tailored, project-specific plan rather than a one-size-fits-all approach.

To successfully execute the plan, the entire project team—including the design team, construction team, and building ownership—must be aware of the building’s unique moisture management risks and the strategies identified to manage those risks.

Communication between teams is critical, as is clarity about who is responsible for preparing and implementing different aspects of the plan. It is common for design specifications to require the contractor to develop a written plan and submit it for approval. The design team may specify certain elements to include in the plan, such as:

- Construction schedule and delivery plans

- Protocols for monitoring the mass timber throughout all construction stages (factory, transportation, storage, and installation)

- Method of determining moisture content and required recordkeeping

- A schedule of materials with minimum expected protection requirements

- Acceptable moisture content prior to covering mass timber elements with acoustic mat, concrete or gypsum-based topping, or membranes

- Acceptable mass moisture content thresholds throughout all construction phases

- Methods to prevent or limit moisture exposure using passive protection measures (membranes, tarping, tenting, and protection details)

- A details package

- Water removal and drainage plans

- Methods of drying to limit excessive shrinkage and checking

- Expected response to a rain or snow event

- Methods of removing water stains

In addition to the written plan, the moisture management plan package submitted to the design team prior to construction typically includes a number of supplemental documents. These documents may include checklists, a site plan, and information such as roles and responsibilities, field visits, moisture measurement/monitoring locations, and mock-up requirements.

Mitigating the Risk of Trapped Moisture

Common conditions that can increase the risk of trapped moisture can be anticipated and addressed in the moisture management plan. They include:

- Low-permeance membranes. If materials with low vapor permeance are used, the mass timber panels need to be dry (with a moisture content below 16%) prior to the installation of these materials to prevent trapping water within the panels. Low vapor-permeance materials may include roofing materials, waterproofing membranes, rubber acoustic mats, or concrete toppings.

- Factory protection wraps. Panels and glulam beams typically arrive on site wrapped in lumber wrap to protect the wood from dirt and weather while in transit. Loose sheet lumber wrap is not intended to be a long-term solution because it can trap moisture, leading to swelling and/or mold. If the mass timber is stored prior to installation, the wrap should be cut at the bottom and the edges loosened to release moisture and allow airflow around the wood.

- Interior finishes. Some tall timber buildings require noncombustible protection to be installed during construction for fire protection. Adding gypsum or other moisture-sensitive materials to the inboard side of exposed mass timber elements increases their moisture sensitivity. These materials can hold water against the wood, limit drying, and visually conceal wet areas. The risk of trapped moisture can be reduced by quickly making the floors, walls (including installed windows), and roofs above these areas watertight.

- Concrete toppings and acoustic mats. Concrete toppings and acoustic mats can trap moisture at the top of a mass timber floor panel. Although this moisture may eventually dry, this process can take up to a year or longer. By this time, mold and decay of the wood may already have begun. Therefore, it is recommended that the design team specify a maximum moisture content of the mass timber, such as 16%, prior to installation of the acoustic mat and/or topping. Avoid installing a concrete topping before the mass timber assembly is shielded by watertight walls or construction barriers and a watertight level above (such as a roof or floor with a membrane). If water reaches the concrete topping, it is likely to travel through the concrete at cracks, interfaces, and the topping perimeter, becoming trapped beneath.

- Splines and details. Water can penetrate deep into mass timber panels where the edge grain is exposed. These areas often include joints, such as those between panels and common building details, such as roof-to-wall interfaces, column-to-floor connections, penetrations, wall edges, structural attachments, and parapets. Site-installed protection measures are needed at all building details; an effective approach is to install protection details directly after the mass timber panels are placed.

Moisture Management in Tall Buildings

Mass timber in tall buildings requires areas of noncombustible protection to be installed during the construction phase for fire protection. Adding gypsum or other moisture-sensitive materials to the underside of exposed mass timber elements means the floor above needs to be watertight to avoid trapping moisture in the wood, at the interfaces with the gypsum, or within the gypsum itself (Figure 2). As a result, these buildings usually warrant more robust and carefully planned protection.

FIGURE 2 (right): Fire-rated gypsum installed on the underside of a CLT floor mid-construction

Construction Sequencing

Moisture management plans often provide instructions for sequencing construction activities to limit moisture exposure of the mass timber elements. Strategies for protecting the wood include:

- Sequencing the delivery of panels. Sequencing panel delivery to coincide with installation will reduce or eliminate the need for on-site storage. Just-in-time delivery is common and minimizes the risk of damage.

- Sequencing exterior wall installation in rhythm with the floors. One benefit of mass timber is that no shoring and curing time is needed before exterior wall and mechanical/electrical/plumbing (MEP) installers can begin work.

- Sequencing to avoid trapping moisture under concrete toppings. The project sequencing and schedule can be modified to reduce the risk of trapping moisture under concrete toppings.

Moisture Protection and Removal

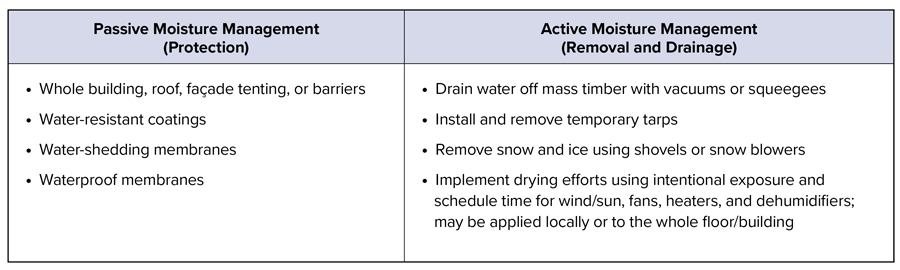

Moisture protection of mass timber is a combination of passive and active moisture management strategies (Table 1).

TABLE 1: Types of passive and active moisture management for mass timber buildings

For passive protection, moisture protection membranes are available with varying levels of robustness. More robust options may come with a more robust initial price tag, but inadequate protection may also lead to increased labor costs for water removal, stain removal, and other remediation efforts. Therefore, risk and budget must be balanced when creating the moisture management plan. The moisture protection membrane(s) selected for a project will depend on a variety of project-specific considerations, including the risk factors discussed earlier. The risk evaluation and membrane protection selection process is extremely important to ensure the level of moisture protection is adequate for the moisture exposure on site. For more information on selecting an adequate moisture protection membrane, refer to Moisture Management Strategies for Mass Timber Buildings (V3) by RDH Building Science.

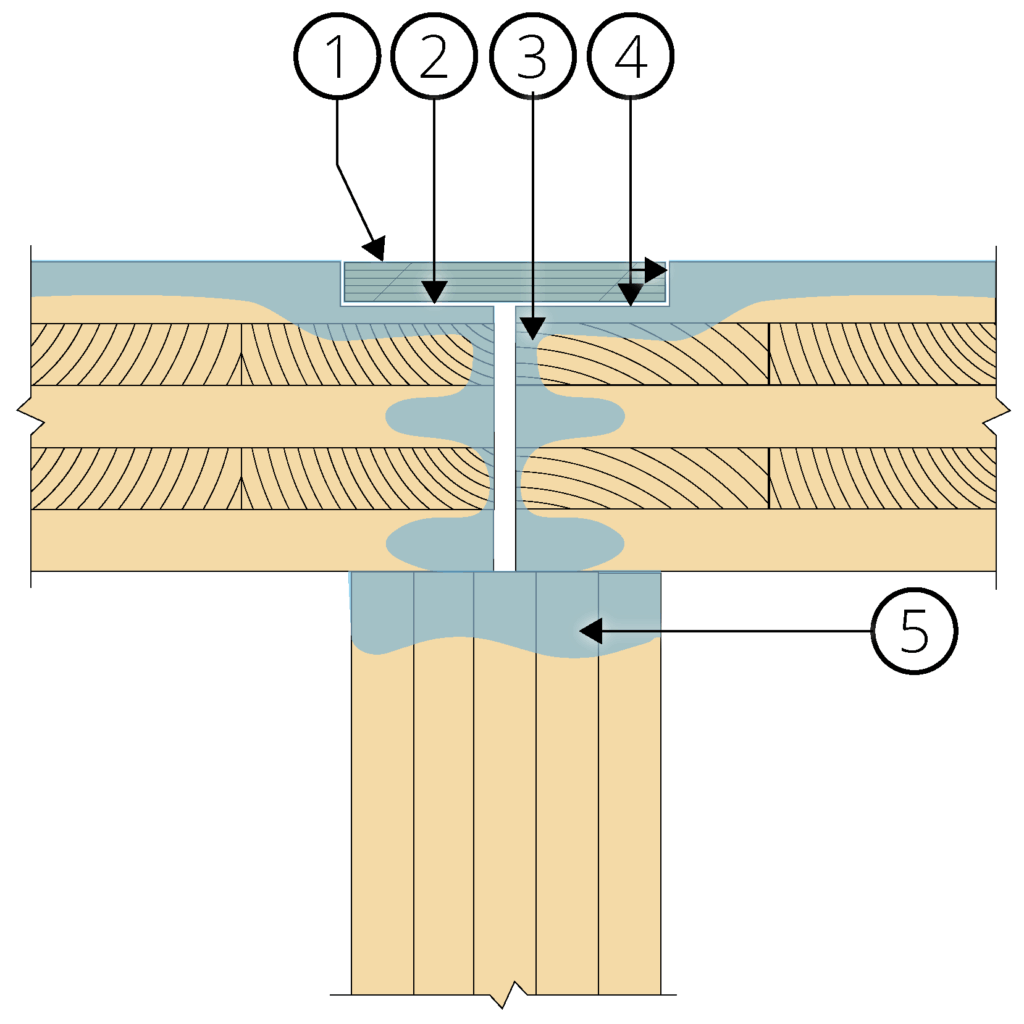

In addition to protection membranes for the mass timber panel faces, site-installed protection measures are needed at building details and interfaces (Figure 3 and Figure 4). An effective approach is to install protection details immediately after mass timber panel placement.

Important elements of a moisture protection plan that can be implemented by the general contractor are water removal and drainage. Water should be diverted off and away from the mass timber elements and toward drains or off the edges of the floor or roof (Figure 5 and Figure 6 ).

Moisture Measurement and Monitoring

A key part of executing a moisture management plan is to visually inspect and take moisture content readings of mass timber elements on an ongoing basis. When done effectively, moisture readings are a valuable tool that helps the construction team identify areas where moisture is becoming trapped, monitor drying trends, improve the team’s moisture management methods, and collect baseline data on the wood structure before encapsulation, roofing, or other activities that conceal the wood.

Taking moisture readings at appropriate times and locations is an effective use of project resources. Readings are taken using a moisture meter with pin probes (or extension probes for deeper measurements). By taking readings that reflect the overall wetting and drying conditions at each level and condition, and at areas most susceptible to concealed moisture and moisture absorption, the project team can understand which areas are wet and to what extent. For efficiency, moisture content readings are generally taken shortly after rainfall events and at areas more likely to absorb, trap, or conceal water. Some of these areas include splines (Figure 7), exposed wood, end grains, and protective membrane laps and seams.

FIGURE 7: Concealed wetting at panel splines

Drying

If the mass timber does get wet, drying can be promoted with different methods. Recommended practices include enclosing the room, increasing the temperature slowly, using fans, heaters, or dehumidifiers in short intervals, and monitoring the humidity. Avoid rapidly drying the mass timber to minimize the risk of excessive checking, shrinkage, and/or warping in the wood.

Wood can typically dry out over time when the water source is removed under favorable environmental conditions (sun, wind, or dry air). Cool and damp weather conditions will reduce the ability of the mass timber elements to dry out naturally. However, post-installation drying should not be considered a regular step in the construction of a mass timber building; it should only be done if wetting exceeds the recommended moisture content thresholds.

Stain Removal

Staining occurs when moisture causes tannins to migrate within the wood. It can also appear when moisture causes a chemical reaction between the wood and structural attachments. The project’s moisture management strategies (i.e., membranes, coatings, factory wrapping, drainage) are intended to reduce the severity and likelihood of water exposure; however, stain removal may still be necessary for some projects. Coated, painted, and/or galvanized or stainless-steel connections can minimize the risk of staining at structural attachments.

Stain removal is typically performed after the building is watertight. The preferred approach is to use cleaners recommended by the mass timber manufacturer. Sanding is another option for surface stains but can also remove coatings, which would need to be reapplied. Because of the visual difference between sanded and unsanded areas, the entire element must often be sanded to achieve a consistent finish.

Building Commissioning and Operation

Checking can occur when mass timber is dried too much or too fast, or if drying occurs unevenly. To reduce this possibility, control the building’s indoor conditions (indoor relative humidity and temperature) after the enclosure is complete and during commissioning and operation. Once the building is enclosed, the indoor conditions can be adjusted slowly and in a controlled manner until the desired in-service equilibrium moisture content is met.

Example Scenarios

Consider moisture management approaches for the following mass timber project scenarios.

- Example 1: Project with a low moisture exposure risk. In this case, a low-level protection strategy may be acceptable using a factory-applied wood sealer from the manufacturer, taped joints, and perimeter barriers/tarps. If the timber gets wet, immediate action would be required using brooms or squeegees to remove water from horizontal members and fans for drying. These actions would be necessary until the moisture level has been reduced to 16% or lower. If the moisture content is above 16%, the application of a concrete topping or finishes may be delayed and labor efforts to dry the timber may be necessary. The general contractor would also expect to remove staining on glulam beams and the underside of CLT panels once they are dried.

A more robust protection approach would include a factory-applied peel-and-stick moisture protection membrane product with joints, edges, and connections sealed in the field. In this case, action would still be required to remove water in a timely manner. The response time would depend on the material properties and whether the protection is water shedding, water resistant, or waterproof to standing water, and also its vapor permeance. - Example 2: Project with a high moisture exposure risk. In this case, passive moisture protection may require a temporary roof or a fully waterproof membrane, both of which would be edge-drained or sealed to drain ports that drain water to the exterior of the building. This approach would require no immediate active water removal after a rain event and present a low risk of wetting and need for stain removal efforts. Monitoring is still required to ensure water is not able to get underneath the membrane.

Conclusion

Although moisture management planning for mass timber buildings can be a complex undertaking, it is also quite achievable. The guide Moisture Management Strategies for Mass Timber Buildings (V3) by RDH Building Science describes a three-step process for assessing moisture risks in a mass timber building, creating a moisture management plan, and implementing that plan during construction. The guide also includes moisture risk assessment tools and case studies of mass timber projects.

References

RDH Building Science Inc. (2025). Moisture Management Strategies for Mass Timber Buildings V3.0

RDH Building Science Inc. (2023). Mass Timber Building Enclosure Best Practice Design Guide V2.2

Finch, G. RDH Building Science Inc. (n.d.). Mass Timber Moisture Management Planning

Straube, J. RDH Building Science. (2022). Rainscreens: When, Where, and Why?

WoodWorks – Wood Products Council. (2021). U.S. Mass Timber Construction Manual.

Binational Softwood Lumber Council. (2017). U.S. Nail-Laminated Timber Design and Construction Guide 1.0.

1U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. (2010). Wood Handbook: Wood as an engineering material. (2010). General Technical Report FPL–GTR–190.

Article contributed by RDH Building Science